Products we Manufacture

VIEW ALL

CNC Vertical Turn Mill

CNC Double Column Milling

CNC Floor Boring Machine

CNC Slant Bed Turn Mill

CNC Vertical Turning Lathe

CNC Gantry Milling Machine

CNC Vertical Turning Lathe (Turret)

5-Axis Double Column Milling

5-Axis Gantry Milling Machine

CNC Vertical Turn Mill (Turret)

Conventional Horizontal Boring

Conventional Vertical Turning Lathe

Discover the legacy of innovation at Sahil Machines

Driven by a vision to transform the company into a temple of technology through teamwork, Sahil Alloys & Machine Tools has continually evolved. Continuous process improvement and the adoption of cutting-edge technology have led Sahil Alloys & Machine Tools to become one of the world's leading manufacturers of CNC machines, with a significant market share both in India and globally.

ABOUT US60+

Years of Legacy

20+

Countries Served

5000+

Machine Installations

See our Machines in Action

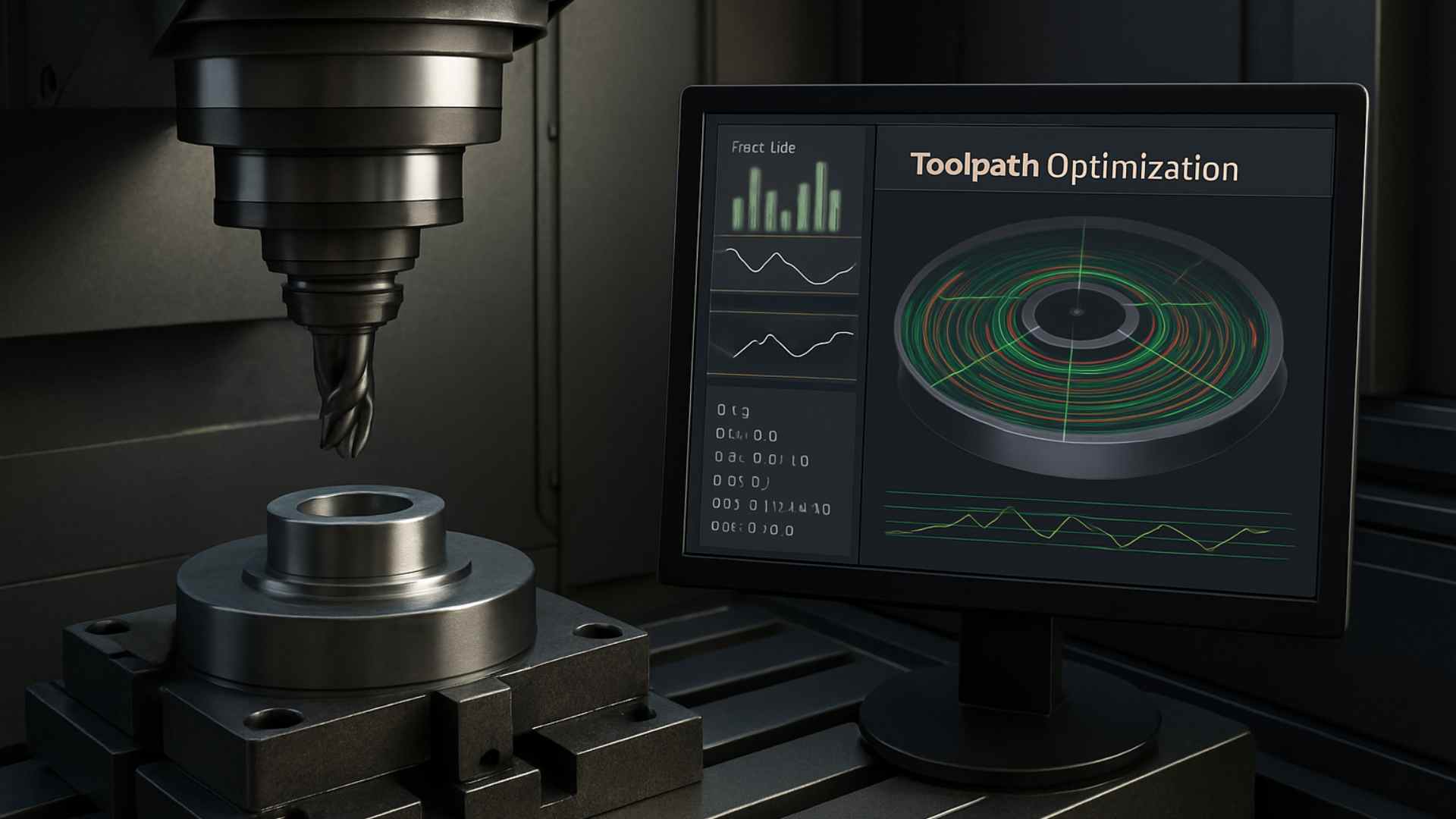

Leading the Way in CNC Innovation

VIEW ALLLatest news from our blog

VIEW ALLLearn more about our services from our FAQs

Yes, these machines are versatile and can efficiently handle a wide range of materials, including metals, plastics, and composites. With appropriate tooling and cutting strategies, they deliver exceptional results across diverse applications.

Regular maintenance, including lubrication, alignment checks, and tooling inspections, is crucial for keeping your VTL in top condition. Follow manufacturer recommendations for maintenance schedules and operating procedures to maximise efficiency and extend the machine's lifespan

These lathes feature fast spindle speeds, rapid tool changes, and advanced control systems, allowing for high-speed and high-precision machining. Additionally, their ergonomic design contributes to operator efficiency.

Regular maintenance and calibration to ensure optimal performance. Utilise advanced cutting tools and machining strategies for increased efficiency and quality. Implement proper programming techniques to minimise cycle times and maximise throughput. Invest in operator training to maximise productivity and minimise errors. Stay updated with technological advancements and software updates to leverage the latest features and capabilities.

The CNC Surface Wheel Lathe operates by securing the wheel on a spindle and rotating it while a cutting tool, controlled by computer programming, precisely removes material from the surface to achieve the desired shape and finish.

Unlike traditional milling machines that operate on three axes (X, Y, and Z), a 5-axis gantry milling machine adds two rotational axes (A and B), enabling machining operations from multiple angles. This capability allows for the production of complex parts in a single setup.