How Augmented Reality (AR) is Transforming CNC Machine Programming and Troubleshooting

Augmented Reality (AR) is changing the way CNC machine programming and troubleshooting are done. Learn how this innovative technology improves accuracy, reduces errors, and enhances operational efficiency.

July 09, 2025

Share:

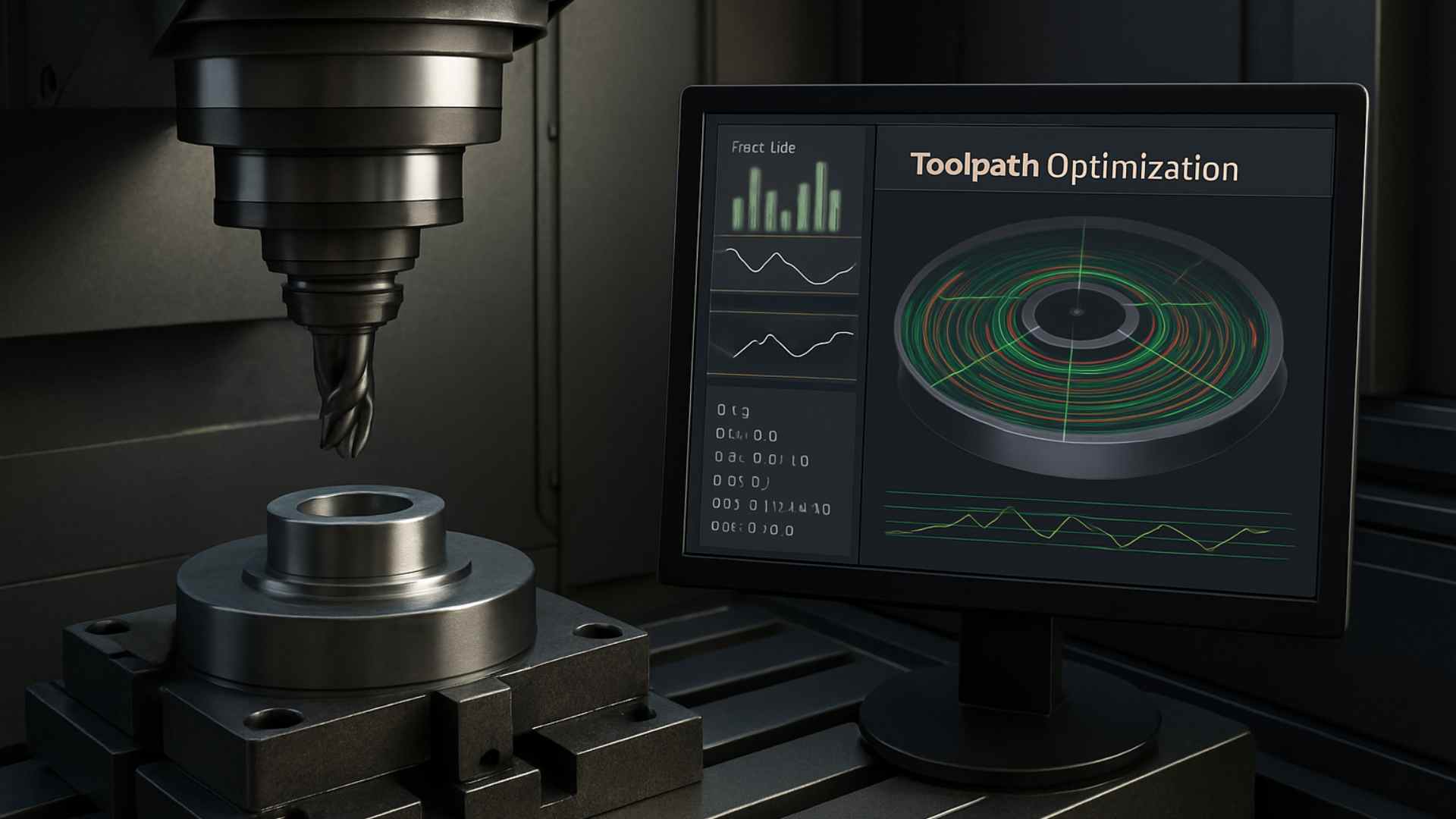

In the fast-paced world of manufacturing, precision, efficiency, and accuracy are paramount. CNC (Computer Numerical Control) machines are at the core of modern manufacturing, driving processes that require high precision and repeatability. However, programming and troubleshooting these complex machines can be time-consuming and prone to errors. This is where Augmented Reality (AR) steps in, providing groundbreaking solutions that enhance CNC machine programming and streamline troubleshooting processes.

Augmented Reality (AR) is no longer just a futuristic concept—it's a powerful tool that is transforming CNC machine programming and maintenance. By overlaying digital information on the physical world, AR enables operators to visualize, interact with, and optimize their CNC systems more effectively than ever before. In this blog, we will explore how AR technology is revolutionizing CNC operations, improving machine setup, reducing downtime, and enhancing overall manufacturing performance.

What is Augmented Reality (AR)?

Augmented Reality (AR) involves the integration of digital content—such as graphics, images, or data—into the real world through devices like smart glasses, smartphones, or tablets. Unlike Virtual Reality (VR), which immerses users in a completely virtual environment, AR enhances the real world with additional information, creating a mixed-reality experience.

In the context of CNC machining, AR brings digital overlays to life, allowing operators and engineers to visualize complex machine data, programming instructions, and step-by-step guidance directly in the physical workspace. By offering real-time feedback, AR enhances the user experience and supports decision-making in ways that traditional methods simply cannot.

The Role of AR in CNC Machine Programming

CNC machine programming is a complex task that requires precision and a deep understanding of the machine’s capabilities. Traditional programming methods often involve writing lengthy code, setting up machines manually, and relying on trial and error to get the desired output. AR technology has drastically changed this process by simplifying programming and making it more intuitive and efficient.

1. Visualizing the Program Code

AR can display program code directly overlaid onto the physical CNC machine. As the machine is being programmed, operators can view the toolpath, cutting simulations, and even monitor machine movements in real time. This digital overlay helps operators visualize how the machine will behave before starting the actual machining process, reducing the risk of errors and improving the accuracy of the programming.

For example, AR glasses or tablets can display a real-time visualization of the CNC tool’s path as it cuts through the material. This gives the operator an immediate understanding of potential issues, such as tool collisions or incorrect toolpaths, allowing them to make corrections before the machine starts running.

2. Streamlining Machine Setup

Setting up CNC machines for a new job can be time-consuming, requiring operators to follow detailed manual instructions. With AR, the setup process becomes more efficient and user-friendly. AR-based systems can overlay setup instructions on the machine’s physical components, guiding the operator step-by-step through the entire process.

This means that operators can quickly identify the correct tool, ensure the correct part is installed, and verify that machine settings are optimized—all with minimal training. By providing real-time visual guidance, AR helps reduce human error during the setup phase, improving both speed and accuracy.

3. Interactive Programming Assistance

AR also allows for interactive programming. Operators can use gestures or voice commands to adjust programming settings while interacting with the AR interface. For example, they could alter feed rates, cutting speeds, or tool parameters directly in the AR environment. This level of interactivity makes it much easier for operators to make real-time changes to programs, ensuring that the machining process runs smoothly and efficiently.

How AR Enhances CNC Troubleshooting

Troubleshooting CNC machines can be one of the most challenging aspects of maintaining high operational efficiency. When a problem arises, operators and technicians often need to diagnose the issue, which may require consulting technical manuals, performing tests, or relying on guesswork. AR technology is changing this by providing real-time troubleshooting solutions that guide operators through diagnosing and resolving issues.

1. Real-Time Diagnostics

Using AR, technicians can access real-time diagnostics on machine performance and health. For example, AR can display real-time information about machine conditions such as temperature, pressure, and tool wear, overlaid directly onto the physical machine. This enables technicians to quickly pinpoint issues like overheating, abnormal vibrations, or faulty sensors without needing to manually check each component.

By providing clear visual indicators, AR simplifies the troubleshooting process and reduces the time required to identify the root cause of a problem. It can also suggest corrective actions based on data from the machine, helping technicians address the issue more efficiently.

2. Remote Assistance and Collaboration

One of the most significant benefits of AR in troubleshooting is the ability to offer remote assistance. Technicians or engineers can use AR technology to provide step-by-step guidance to operators on the shop floor, even if they are located remotely. For example, an experienced technician can view the shop floor through the operator’s AR headset and provide real-time instructions or demonstrate how to resolve an issue.

This reduces downtime by allowing expert guidance to be provided without the need for a technician to be physically present on-site. Remote troubleshooting also ensures that operators have access to expert knowledge at all times, even during critical situations.

3. Training and Knowledge Transfer

AR not only aids in troubleshooting but also facilitates training. New operators or maintenance technicians can learn to troubleshoot machines by viewing AR-based tutorials and interactive guides. This hands-on approach enhances learning and speeds up the training process, enabling workers to resolve issues more effectively and independently.

Benefits of AR in CNC Machine Programming and Troubleshooting

- Increased Efficiency: AR reduces setup times, programming errors, and troubleshooting downtime by providing real-time, visual guidance.

- Improved Accuracy: By visualizing programming instructions and machine movements, AR reduces human error and improves the precision of CNC machining operations.

- Reduced Training Time: AR-based training helps operators and technicians quickly become proficient in machine programming and troubleshooting, reducing the need for extensive classroom training.

- Cost Savings: By minimizing errors, reducing downtime, and improving machine uptime, AR can contribute to significant cost savings in the long run.

- Enhanced Collaboration: Remote troubleshooting and assistance enable experts to support operators without being physically present, fostering better collaboration and faster issue resolution.

Conclusion

Augmented Reality is transforming CNC machine programming and troubleshooting by providing intuitive, real-time guidance that improves machine setup, reduces errors, and enhances operational efficiency. By integrating AR technology into CNC operations, manufacturers can achieve higher precision, reduce downtime, and streamline troubleshooting processes, ultimately leading to smarter, more efficient manufacturing environments.

Explore more from Sahil Machines

FAQ

AR improves CNC machine programming by allowing operators to visualize the toolpath, cutting simulations, and machine movements in real-time. This reduces errors, enhances setup accuracy, and provides interactive programming assistance.

AR enhances troubleshooting by providing real-time diagnostics and visualizing machine conditions. It allows technicians to diagnose issues quickly, access remote assistance, and resolve problems more efficiently.

Yes, AR is an excellent tool for training CNC operators. It offers interactive, hands-on learning experiences by providing step-by-step guidance and visualizing machine programming and troubleshooting processes.

The main benefits include increased efficiency, improved accuracy, reduced training time, cost savings, and enhanced collaboration through remote troubleshooting and support.

AR assists with machine setup by overlaying setup instructions and machine parameters directly onto the physical machine, guiding operators step-by-step through the process and reducing errors.

Follow Us:

Latest Posts

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.