How Autonomous CNC Machines Are Changing the Future of Smart Factories

Discover how autonomous CNC machines are shaping the future of smart factories. Learn about their impact on production efficiency, cost reduction, and the evolution of manufacturing automation.

July 09, 2025

Share:

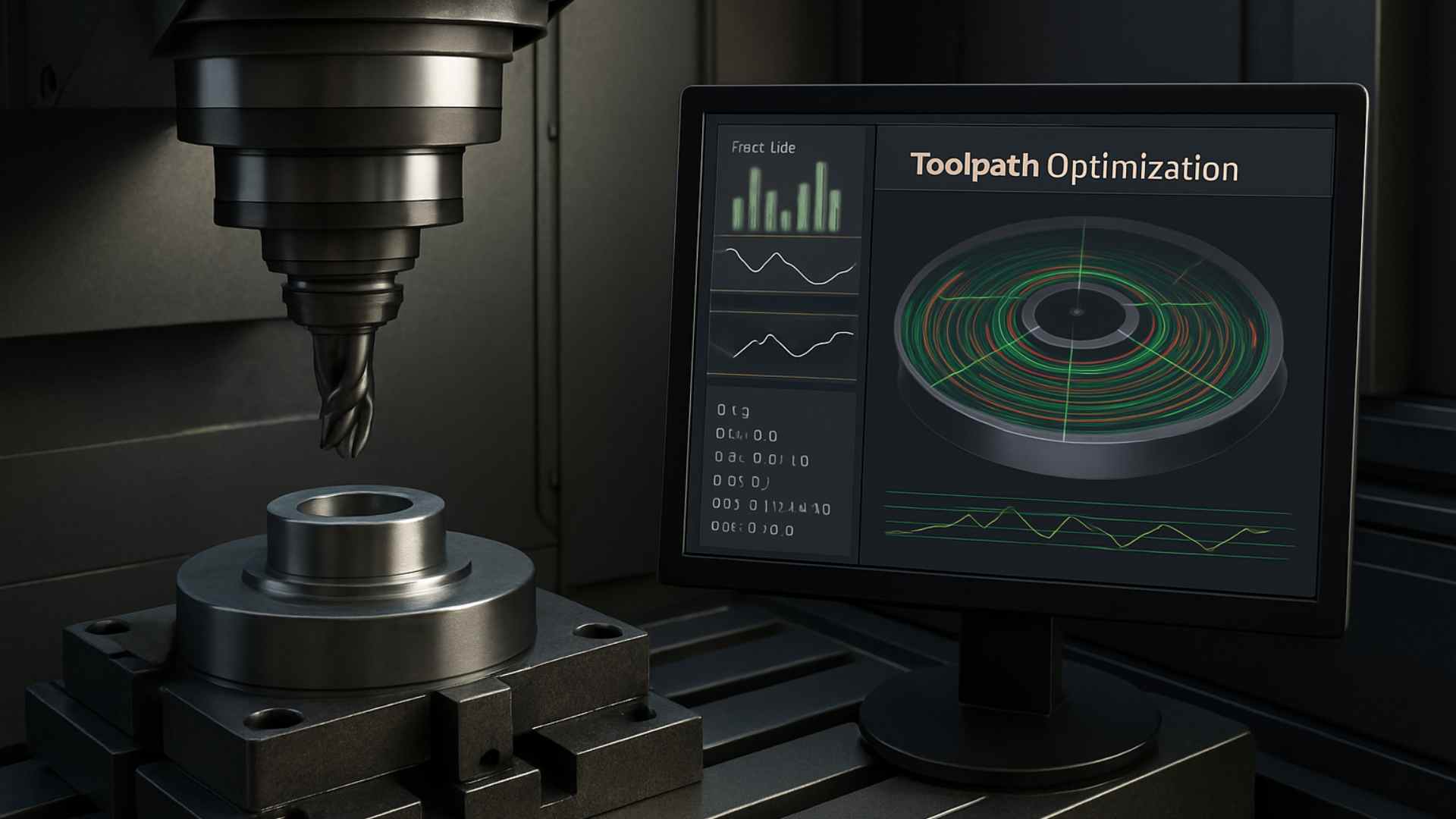

The manufacturing industry has always been a driving force of innovation, and with the rise of autonomous CNC (Computer Numerical Control) machines, the future of manufacturing is on the brink of a transformative shift. As Industry 4.0 continues to redefine the way factories operate, autonomous CNC machines are at the forefront, playing a pivotal role in the development of smart factories.

These machines are changing the landscape of production by improving efficiency, reducing labor costs, and enabling real-time decision-making. In this blog, we will explore how autonomous CNC machines are not only enhancing current manufacturing processes but also shaping the future of smart factories and manufacturing automation.

What Are Autonomous CNC Machines?

Autonomous CNC machines are advanced, self-operating machines that use artificial intelligence (AI), machine learning, and robotics to perform CNC machining tasks with little to no human intervention. Unlike traditional CNC machines, which require human operators to input commands, monitor the process, and make adjustments, autonomous CNC machines are equipped with the ability to learn, adapt, and make decisions on their own based on the data they receive.

These machines can perform tasks such as material handling, tool changing, program adjustments, and even predictive maintenance without requiring constant human supervision. They are integrated into the broader ecosystem of smart factories, where they communicate with other machines, sensors, and systems to optimize production processes.

The Role of Autonomous CNC Machines in Smart Factories

Smart factories, also known as intelligent factories, represent the future of manufacturing, characterized by highly automated and digitally integrated production processes. Autonomous CNC machines are a key component of these factories, enabling the seamless flow of information and improving overall operational efficiency. Let's take a closer look at how they contribute to this next-generation manufacturing environment.

1. Enhanced Efficiency and Productivity

One of the most significant advantages of autonomous CNC machines is their ability to work continuously and consistently without the need for breaks or rest. In a traditional manufacturing setting, human operators may face fatigue, leading to decreased productivity and increased risk of errors. Autonomous CNC machines, on the other hand, can operate 24/7, significantly improving throughput and efficiency.

Moreover, these machines can optimize production schedules by automatically adjusting machining parameters, such as speed, feed rate, and cutting depth, based on real-time data. This reduces the chances of bottlenecks and ensures smoother production flows, ultimately leading to higher productivity and shorter lead times.

2. Reduced Labor Costs

The introduction of autonomous CNC machines allows companies to reduce their reliance on human operators for routine tasks such as programming, tool changes, and quality checks. With the ability to perform these functions automatically, manufacturers can operate with fewer employees, thereby reducing labor costs.

Additionally, because autonomous CNC machines can perform tasks without constant supervision, human workers can focus on more complex, high-value tasks such as process optimization, machine maintenance, and quality control, leading to better overall productivity and innovation.

3. Improved Precision and Quality Control

Autonomous CNC machines excel in maintaining precise and consistent machining operations, which is crucial for industries requiring tight tolerances and high-quality standards. These machines are equipped with advanced sensors and feedback systems that enable them to monitor the machining process in real-time, detect errors, and make necessary adjustments on the fly.

By reducing human error and increasing process consistency, autonomous CNC machines help manufacturers achieve higher levels of product quality. Moreover, these machines can continuously gather data throughout the production process, feeding it into a centralized system that allows for real-time quality monitoring and predictive analysis.

4. Predictive Maintenance and Downtime Reduction

In traditional manufacturing settings, machine failures or breakdowns can lead to costly downtime, disrupted production schedules, and expensive repairs. Autonomous CNC machines address this issue through predictive maintenance, a key feature of Industry 4.0.

These machines are equipped with IoT sensors and data analytics capabilities that continuously monitor machine health and performance. By analyzing patterns in the data, autonomous CNC machines can predict when maintenance is required, reducing the likelihood of unexpected failures. This helps manufacturers minimize downtime, extend the lifespan of their equipment, and optimize their maintenance schedules, resulting in significant cost savings.

Autonomous CNC Machines and Industry 4.0

The concept of Industry 4.0 is centered around the integration of smart technologies such as the Internet of Things (IoT), artificial intelligence (AI), big data analytics, and robotics into manufacturing operations. Autonomous CNC machines are one of the most tangible examples of how Industry 4.0 is transforming the manufacturing landscape.

By leveraging data-driven insights, autonomous CNC machines can make informed decisions about when to adjust parameters, replace tools, or alter production schedules. This self-optimization enables manufacturers to adapt quickly to changing market demands, supply chain disruptions, or material shortages. Furthermore, autonomous machines can communicate with each other and with other systems in the factory, creating an interconnected, intelligent ecosystem that can autonomously manage production processes.

Integration with Other Smart Technologies

Autonomous CNC machines are not standalone entities—they are part of a larger, interconnected ecosystem of smart technologies within a smart factory. These machines work seamlessly with other automated systems, such as:

- Robotic arms for material handling and assembly

- Automated guided vehicles (AGVs) for parts transport

- Quality control systems for real-time inspections

- ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems) for supply chain and production management

This level of integration allows for highly flexible, adaptive, and efficient production processes that can easily respond to shifts in demand, material availability, and market conditions.

Challenges and Future Outlook

While autonomous CNC machines offer numerous benefits, their implementation comes with some challenges. For example, the initial investment required for autonomous systems and smart factory infrastructure can be significant. Additionally, the integration of new technologies into existing manufacturing processes may require extensive upgrades to machines, software, and employee training.

However, as the technology continues to evolve and become more cost-effective, the adoption of autonomous CNC machines in smart factories is expected to increase. Manufacturers that embrace these innovations will be better positioned to stay competitive in an increasingly automated and data-driven world.

Conclusion

Autonomous CNC machines are at the forefront of the smart factory revolution, ushering in a new era of manufacturing automation. By enhancing efficiency, reducing labor costs, improving precision, and enabling predictive maintenance, these machines are transforming production lines worldwide. As Industry 4.0 continues to evolve, the role of autonomous machines in shaping the future of manufacturing will only become more significant. Embracing these technologies will be essential for manufacturers looking to stay competitive and meet the demands of a rapidly changing industrial landscape.

Explore More from Sahil Machines

FAQ

Autonomous CNC machines are advanced, self-operating machines that use artificial intelligence, machine learning, and robotics to perform machining tasks with minimal human intervention. They can handle tasks like tool changes, programming, and maintenance automatically.

Autonomous CNC machines enhance factory efficiency by working continuously, optimizing production schedules, and maintaining high precision. They eliminate bottlenecks and increase productivity by performing tasks without human supervision.

Yes, autonomous CNC machines can reduce labor costs by automating routine tasks and allowing workers to focus on more complex and high-value responsibilities. This results in fewer employees needed for operations.

Autonomous CNC machines maintain consistent precision and can make real-time adjustments to ensure the highest quality standards. They are equipped with sensors that monitor the machining process, enabling continuous data collection and analysis for better quality control.

Yes, autonomous CNC machines are a key component of Industry 4.0, as they leverage smart technologies like AI, IoT, and big data analytics to optimize production processes and improve manufacturing efficiency.

Follow Us:

Latest Posts

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.