How CAM Software is Evolving to Meet the Demands of Next-Gen CNC Machines

As CNC machines become smarter and more advanced, CAM software is evolving rapidly to match their pace. This blog explores the key innovations driving CAM's transformation in the age of Industry 4.0.

July 09, 2025

Share:

The manufacturing world is changing—fast. With the emergence of next-generation CNC machines, there's a growing demand for CAM (Computer-Aided Manufacturing) software that can do more than just convert designs into tool paths. Today, CAM tools need to be intelligent, connected, and adaptive. From AI integration to real-time feedback loops, let’s break down how CAM software is leveling up to meet the demands of modern CNC machining.

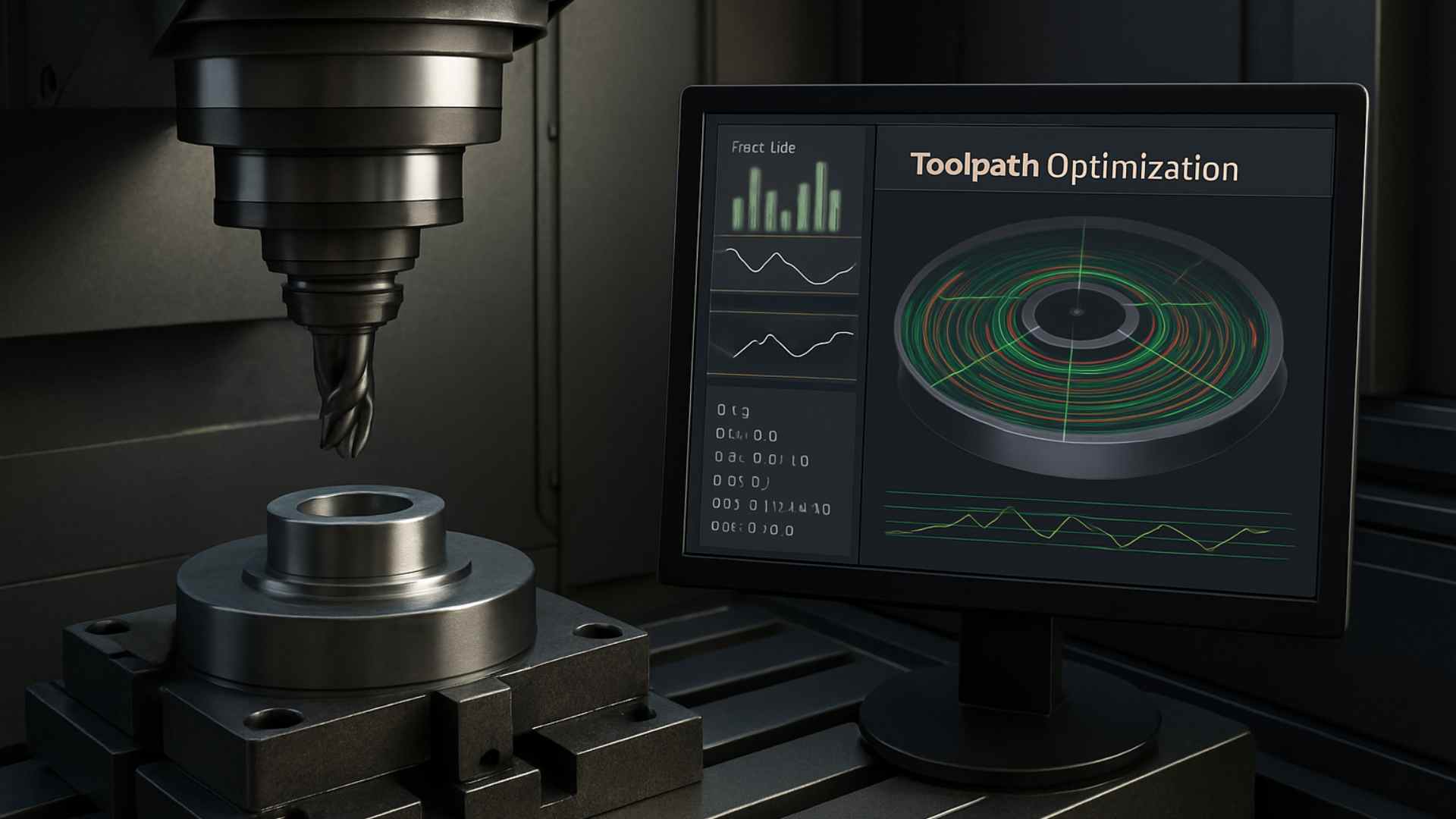

1. Advanced Automation & AI Integration

Modern CNC machines are capable of executing highly complex operations with minimal human intervention. To keep up, CAM software has started incorporating AI and machine learning algorithms that can:

- Automatically select tools and cutting strategies based on the geometry of the part and material.

- Predict potential machining errors or tool collisions before they occur.

- Generate optimized tool paths that reduce cycle times and tool wear.

These AI-driven enhancements significantly reduce programming time and eliminate human errors, helping manufacturers achieve better productivity and precision.

Example: Autodesk Fusion 360 now uses generative design and AI-driven path strategies to suggest optimal machining paths automatically.

2. Cloud-Based CAM Solutions

Cloud integration is no longer just a trend—it's becoming a necessity. Next-gen CAM tools are moving away from traditional desktop-only environments and adopting cloud-based platforms.

Benefits of cloud-based CAM:

- Access from anywhere, on any device

- Faster collaboration between design and production teams

- Automatic updates and backups

- Improved data security and version control

For manufacturers operating in global or multi-location environments, cloud-based CAM ensures a seamless workflow between design, production, and quality control.

3. Tighter CAD/CAM Integration

Gone are the days of disconnected CAD and CAM systems. Modern software now offers seamless integration between design and manufacturing. This unified approach helps:

- Reduce data loss or corruption when transferring files

- Speed up design changes and machining adjustments

- Maintain consistency between the design intent and the final output

For instance, if a designer modifies the model geometry, the CAM software can automatically adjust toolpaths without requiring a full reprogramming of the part.

4. Support for Adaptive Machining

Next-gen CNC machines come with sensors and feedback systems that allow real-time data collection during the machining process. CAM software is now evolving to leverage this data for adaptive machining, where toolpaths and strategies can be modified in real-time based on actual cutting conditions.

- If a tool begins to wear out or vibrate abnormally, the CAM system can adjust feeds, speeds, or even pause operations automatically.

- This not only extends tool life but also reduces scrap and downtime.

5. Enhanced Simulation and Verification

Simulation is a core part of any CAM system, but newer versions are pushing the limits with ultra-realistic, real-time simulations that:

- Show complete machine movements and detect axis overtravel or potential collisions

- Allow users to simulate multiple operations across different workstations

- Support digital twins—virtual replicas of machines and setups for perfect accuracy

These simulations reduce trial-and-error on the shop floor, minimize mistakes, and save on both time and material costs.

6. Multi-Axis and Hybrid Machining Capabilities

As CNC machines now support 5-axis, mill-turn, and hybrid processes (like additive and subtractive machining in one setup), CAM software must support:

- Complex toolpath generation for 5-axis or simultaneous machining

- Accurate control over tool orientation and machine kinematics

- Post-processing tailored to hybrid machines

Modern CAM platforms are being designed to handle these operations with precision, opening up possibilities for complex geometries and custom manufacturing.

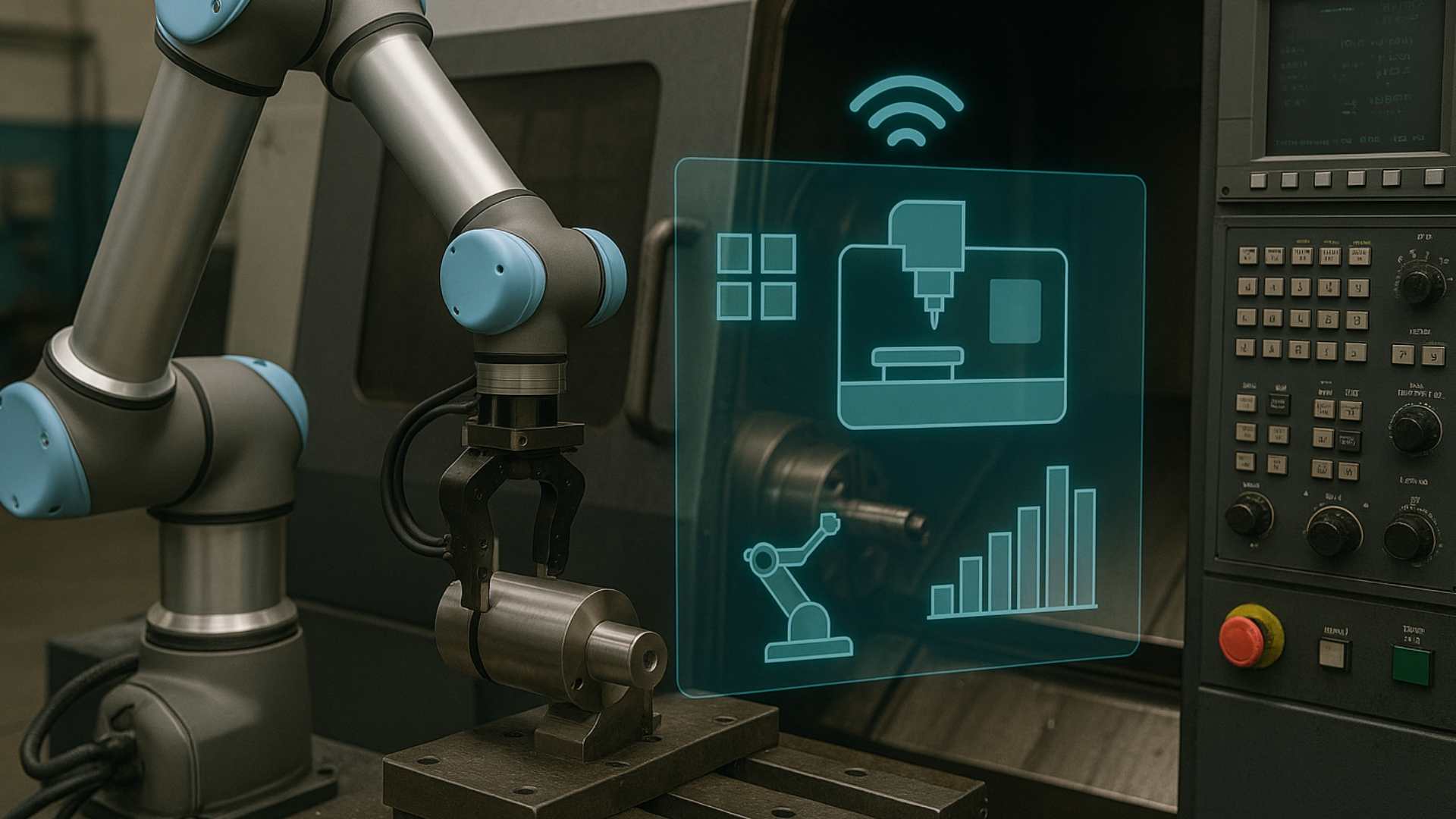

7. Smart Manufacturing & Industry 4.0 Integration

CAM software is becoming a crucial component of smart factories and Industry 4.0. It now connects to:

- ERP and MES systems

- IoT devices and smart sensors

- Automated tool changers and robotics

This deep integration allows for real-time tracking, predictive maintenance, and complete digital workflow from design to final product.

What’s Next for CAM Software?

The future looks promising—and ambitious. We're already seeing advancements in:

- Voice-assisted CAM programming

- AR/VR interfaces for CAM visualization

- No-code CAM solutions for beginners

- Blockchain integration for secure part traceability

As technology continues to evolve, CAM systems will become even more intelligent, automated, and user-friendly—allowing shops of all sizes to stay competitive in a global market.

Conclusion

CAM software is no longer just a bridge between design and production—it’s becoming the brain behind advanced manufacturing. As CNC machines evolve, CAM tools must stay one step ahead with AI, cloud power, multi-axis support, and smart factory integration. Whether you're a small job shop or a global manufacturer, adopting next-gen CAM solutions can make all the difference in staying competitive in today's landscape.

Explore More from Sahil Machines

- CNC Turning Centers — Explore our range of high-precision CNC turning solutions.

- Vertical Machining Centers — Discover powerful VMCs designed for next-gen manufacturing.

- 5-Axis Machining Solutions — Take your production capabilities to the next level with our advanced 5-axis machines.

- Smart Factory Integration — Learn how Sahil Machines enables smart automation and Industry 4.0 solutions.

FAQ

CAM software translates CAD designs into instructions (G-code) that CNC machines follow to manufacture parts. It helps generate toolpaths, select tools, simulate operations, and more.

Next-gen CNC machines are faster, more complex, and capable of multi-axis operations. To unlock their full potential, CAM software must support smarter automation, better integration, and adaptive machining.

Yes, most cloud-based CAM platforms use encrypted data storage and secure access protocols, offering safety as well as real-time collaboration benefits.

Many modern CAM systems now support hybrid manufacturing, including additive and subtractive processes in a single workflow.

AI helps automate tool selection, path optimization, error prediction, and adaptive machining strategies, ultimately improving efficiency and part quality.

Follow Us:

Latest Posts

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.