The Economics of CNC Machining: Cost Reduction Strategies for Small Manufacturers

This blog explores how small manufacturers can reduce CNC machining costs through smart planning, efficient design, material optimization, and technology upgrades—without compromising quality.

July 09, 2025

Share:

Introduction

In the fast-paced world of CNC machining, precision is everything—but so is cost-efficiency, especially for small and medium-sized manufacturers. With limited budgets and increasing competition, small manufacturers must strike a careful balance between delivering high-quality parts and keeping operational costs under control.

While CNC machining is often seen as a capital-intensive process, there are numerous ways to make it economically viable. This blog explores practical strategies that small manufacturers can implement to reduce costs, streamline production, and increase profitability—all without cutting corners on quality.

Understanding the Cost Drivers in CNC Machining

Before diving into cost-cutting strategies, it’s important to understand where the money goes in a CNC machining operation. Key cost contributors include:

- Material costs: Raw materials can be expensive, especially high-grade metals like titanium or Inconel.

- Machine time: Longer machining cycles consume more electricity, wear out tools faster, and reduce throughput.

- Tooling costs: Cutting tools and holders must be replaced frequently, particularly when working with tough materials.

- Labor and setup time: Skilled machinists, machine setup, and programming hours all add to the overhead.

- Post-processing: Tasks like polishing, anodizing, or inspection can significantly extend lead times and labor costs.

Once these drivers are understood, small manufacturers can begin targeting each area with cost-saving solutions.

Smart Cost Reduction Strategies for Small Manufacturers

Here’s how smaller CNC shops can gain a competitive edge by optimizing every part of their process:

1. Optimize Design for Machinability

Many cost inefficiencies start with the design itself. Complex geometries, unnecessary tight tolerances, or deep cavities often require longer machine time and specialized tools. Collaborating with clients or design engineers to improve the manufacturability of a part can greatly reduce costs.

2. Material Selection and Usage Efficiency

Selecting the right material is crucial—not just from a performance standpoint but also in terms of cost and machinability. Soft metals like aluminum are easier (and quicker) to machine than hardened steels, meaning reduced tool wear and faster cycle times.

Also, optimizing nesting and layout in raw material stock can reduce scrap waste significantly.

3. Reduce Tooling Costs through Standardization

Using a wide variety of custom or specialized tools can be expensive. Wherever possible, standardize tool sets across projects to reduce inventory and improve setup times.

Additionally, investing in higher-quality tools may seem costly up front, but they often last longer and deliver cleaner cuts—reducing rework and increasing part yield.

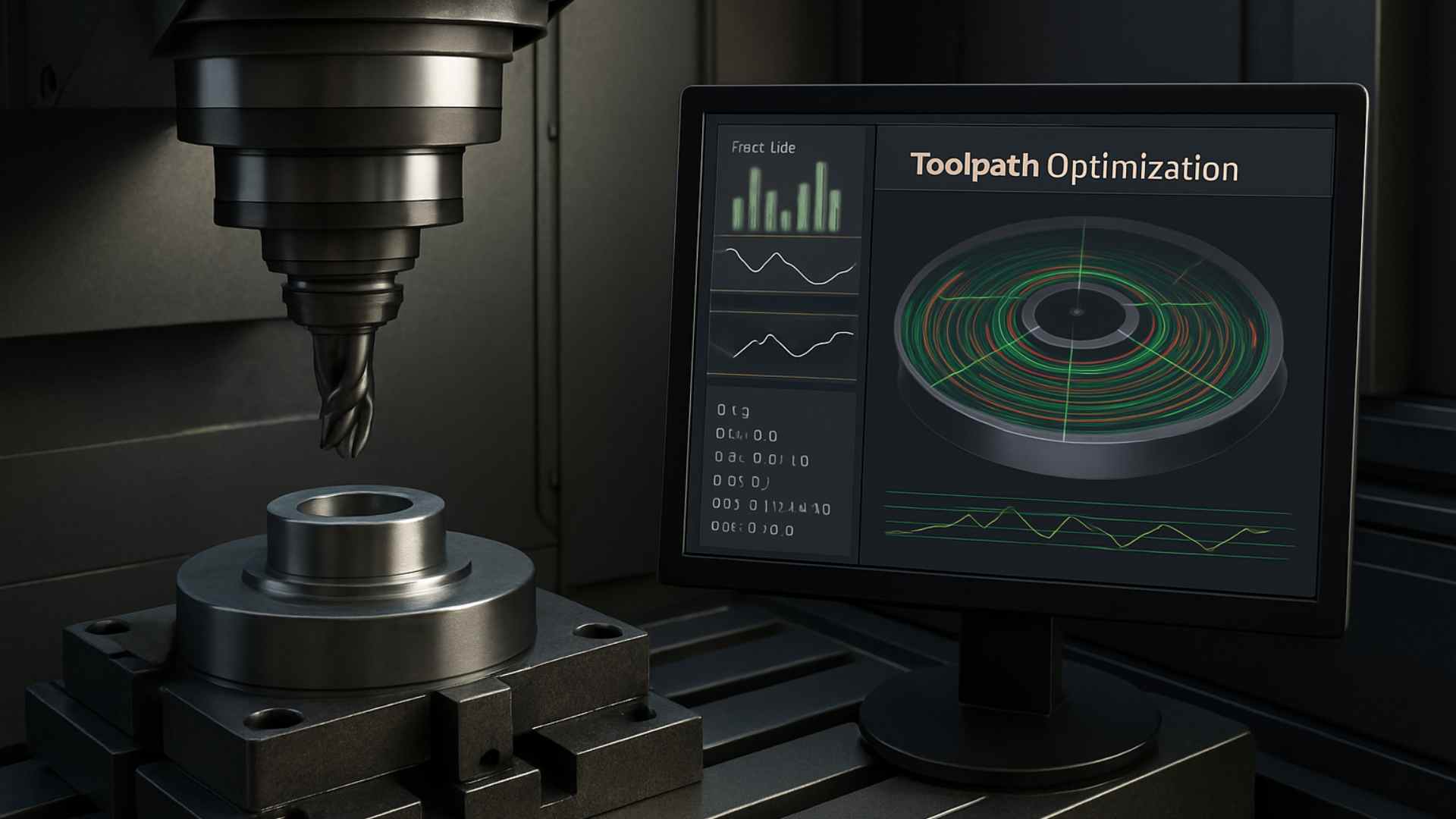

4. Invest in CAM Software and Automation

High-quality CAM (Computer-Aided Manufacturing) software can significantly reduce machine cycle times by generating more efficient tool paths. Some programs also offer simulation features, helping you avoid collisions and setup errors.

Automating repetitive tasks—such as tool calibration, part probing, or even loading/unloading—can improve productivity without adding more labor costs.

5. Batch Production and Scheduling Efficiency

Small shops can save big by grouping similar jobs together. Batching reduces changeovers and setup times, helping maximize spindle uptime.

Proper scheduling ensures that machines are always running or queued with the next job—minimizing downtime between projects.

6. Lean Inventory Management

Holding too much stock ties up cash and increases storage needs. Adopting a just-in-time (JIT) approach to raw materials and finished goods reduces waste and storage costs.

This lean philosophy also applies to tooling and consumables. Order in calculated quantities rather than stockpiling.

7. Preventive Maintenance Saves Long-Term Costs

Unexpected breakdowns can cripple production and lead to expensive repairs. Implementing a preventive maintenance schedule ensures that machines stay in optimal condition and reduces costly downtime.

8. Upskill Your Workforce

Training machinists to operate machines efficiently, optimize tool paths, and identify wear or errors early can significantly reduce errors and wasted material.

Skilled operators are more likely to spot issues before they become expensive problems—and they can run multiple machines at once, increasing output without additional headcount.

9. Outsource Select Processes

Instead of investing in every capability in-house, consider outsourcing complex secondary processes like heat treatment, surface finishing, or intricate EDM machining. This allows small shops to remain lean and agile while delivering comprehensive results.

10. Track KPIs and Costs in Real-Time

Use basic cost-tracking tools to monitor job profitability, machine efficiency, scrap rates, and labor hours. By knowing exactly where the money goes, you can make informed decisions about pricing, investments, and improvements.

Conclusion

CNC machining doesn’t have to be a drain on resources—especially for small manufacturers. With the right strategies, you can control costs, improve margins, and deliver high-quality parts consistently. From smarter design to efficient scheduling and the right tools, the key lies in optimizing each step of the process. As competition grows, those who manage their economics smartly will not only survive—but thrive.

Explore more from Sahil Machines

Check out our additional resources to learn more about CNC machining and how we can help optimize your manufacturing process:

FAQ

Focus on optimizing design, tool selection, and material usage. Also, streamline processes through automation and preventive maintenance.

While full automation may be costly, small-scale automation like bar feeders or probing systems can be highly beneficial.

It depends on the material and machine time. Monitor tool wear in your CNC software and replace them proactively to avoid part defects.

Design for manufacturability, improve tool paths, and ensure your machine calibration is spot on. Also, train operators to recognize early signs of error.

Absolutely. Efficient tool paths, simulation, and tool change optimization in CAM software can save both time and material.

Follow Us:

Latest Posts

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.