The Future of CNC Machining with Digital Twin Technology: Enhancing Accuracy and Predictive Maintenance

Discover how Digital Twin Technology is transforming the future of CNC machining by improving precision, reducing downtime, and enabling predictive maintenance for smarter manufacturing operations.

July 09, 2025

Share:

In the evolving world of manufacturing, Computer Numerical Control (CNC) machining remains a backbone of precision engineering. As the demand for efficiency, accuracy, and uptime continues to rise, manufacturers are turning to a new era of technology—Digital Twin—to revolutionize the way CNC machines operate. This fusion of virtual and physical systems is not just a technological upgrade; it’s a paradigm shift toward smart manufacturing and predictive maintenance.

What is Digital Twin Technology?

A digital twin is a virtual replica of a physical object, system, or process. In the context of CNC machining, it means creating a digital model of the machine, its environment, and its operational behaviors. This digital counterpart receives real-time data from the physical machine, allowing engineers to simulate, monitor, and optimize performance with unprecedented precision.

Essentially, digital twins bring a data-driven intelligence layer to traditional CNC operations.

How Digital Twin Technology Enhances CNC Machining

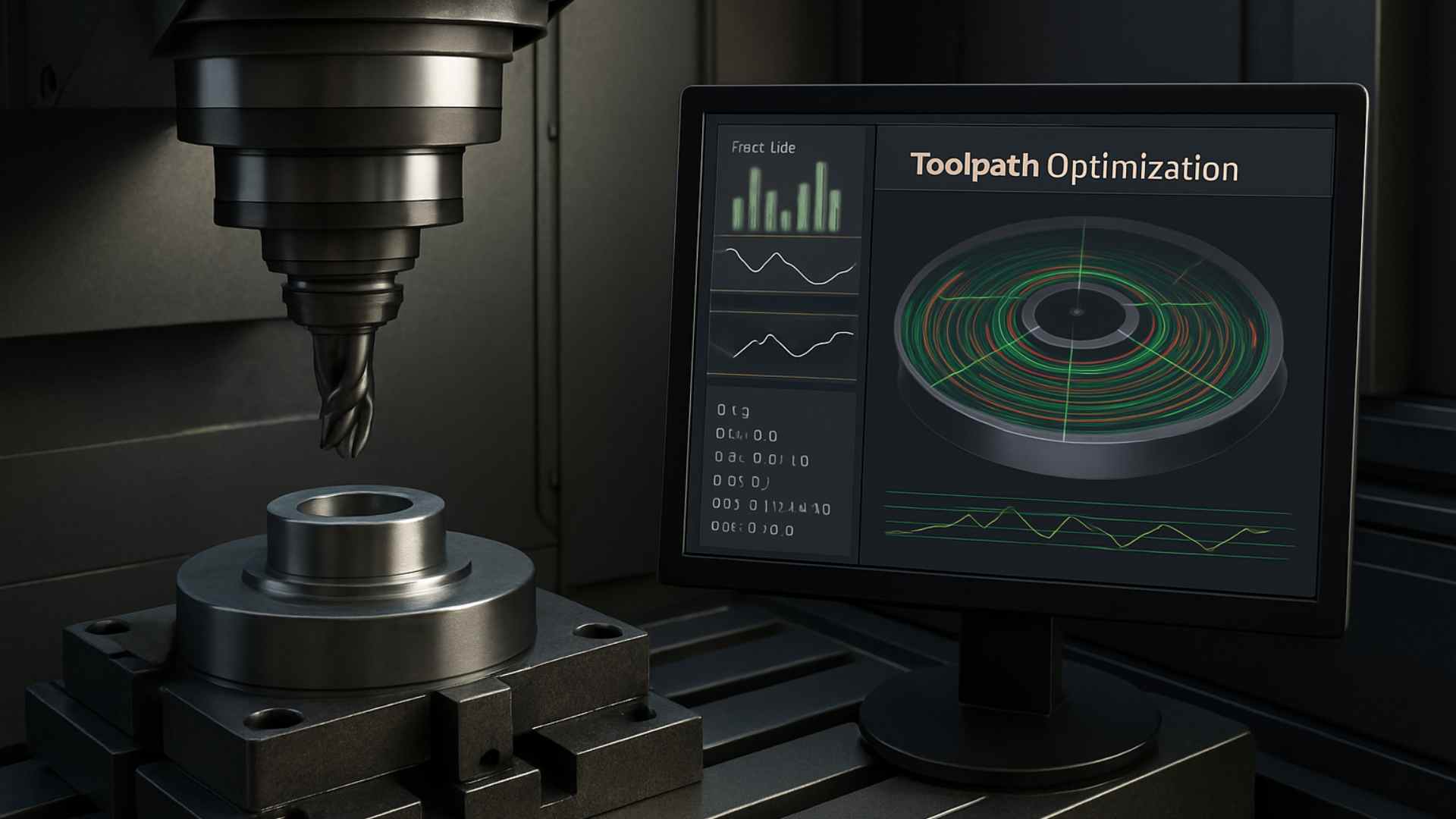

1. Precision and Accuracy

The digital twin continuously mirrors the CNC machine's activities, monitoring factors such as tool wear, temperature changes, vibrations, and machine loads. This allows for:

- Real-time adjustment to maintain tight tolerances.

- Early detection of minute deviations.

- Consistent quality across high-volume production.

Digital twins can also simulate machining processes before actual production begins, ensuring the ideal tool paths, feed rates, and speeds are chosen without trial-and-error on the shop floor.

2. Predictive Maintenance

Traditional CNC machines rely on scheduled or reactive maintenance, leading to either unnecessary downtime or unexpected breakdowns. Digital twin technology enables:

- Real-time health monitoring of components.

- Data analytics that identify wear trends and predict failures before they occur.

- Maintenance scheduling based on actual usage and conditions, not just time intervals.

This shift from reactive to predictive maintenance reduces unplanned downtime, extends machine lifespan, and lowers operational costs.

3. Improved Design and Simulation

With a virtual model of the machining environment, engineers can:

- Run simulations to test new part designs.

- Validate tool paths for complex geometries.

- Identify design flaws early in the product development phase.

This reduces waste, shortens development cycles, and enhances product innovation.

4. Data-Driven Decision Making

CNC machines equipped with digital twins can provide deep analytics into productivity, machine efficiency, and process bottlenecks. With historical and real-time data at their fingertips, manufacturers can:

- Optimize workflow and scheduling.

- Identify root causes of defects or inefficiencies.

- Make faster, more accurate business decisions.

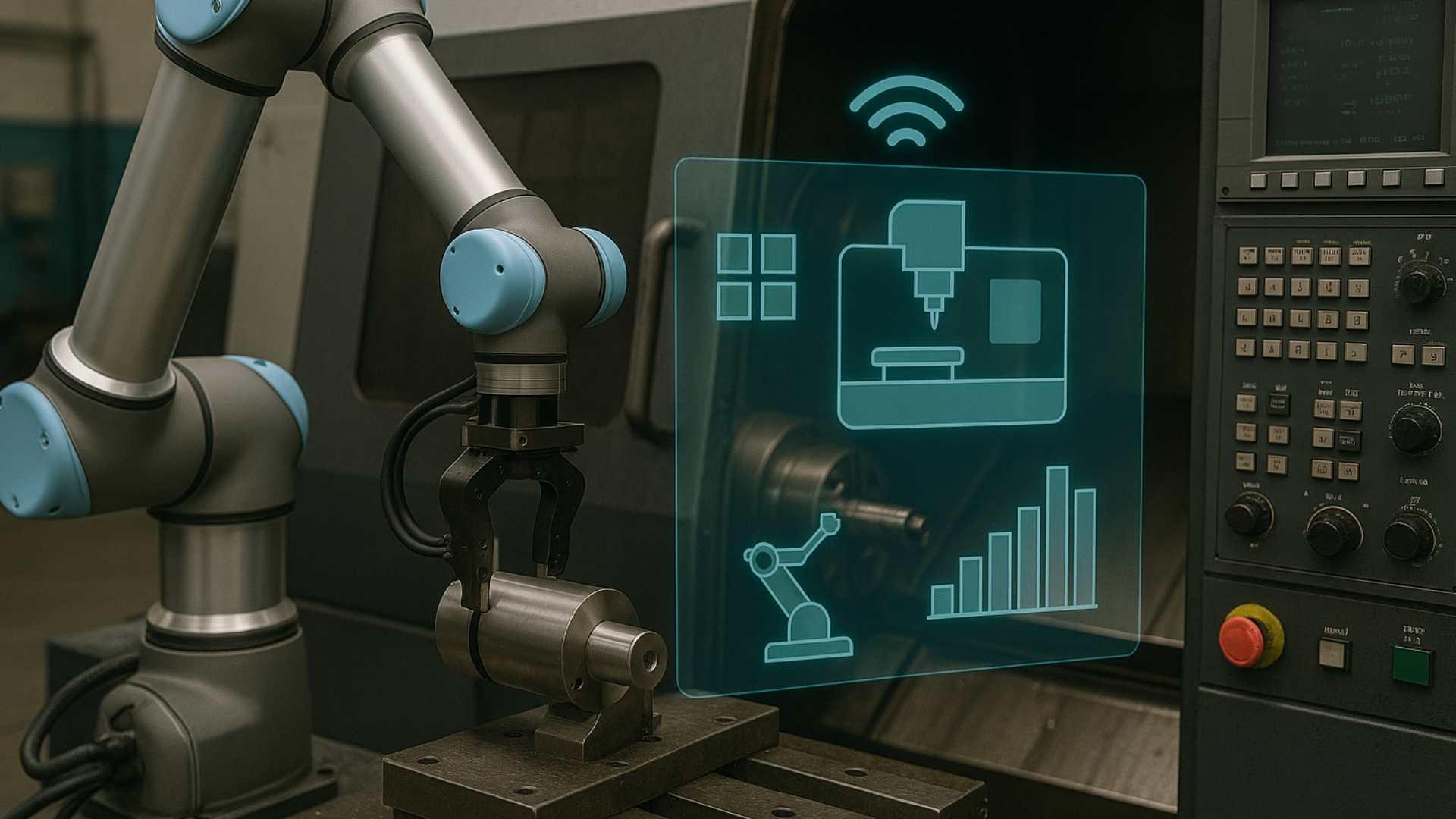

5. Remote Monitoring and Control

In the era of Industry 4.0 and remote work, digital twin technology enables remote access and control of CNC operations. Operators and managers can:

- Monitor machine status from any location.

- Receive alerts for abnormalities or maintenance needs.

- Implement adjustments without being physically present at the machine.

This connectivity improves operational agility and supports distributed manufacturing setups.

The Role of Digital Twin in Industry 4.0

Digital twin technology is a core component of Industry 4.0, which focuses on interconnectivity, automation, machine learning, and real-time data. For CNC machining, this means:

- Integration with IoT sensors for real-time data collection.

- Utilization of AI and machine learning for pattern recognition and prediction.

- Seamless connection with ERP and MES systems for smart factory operations.

As a result, CNC machines evolve from isolated tools into interconnected, intelligent assets within a broader manufacturing ecosystem.

Challenges and Considerations

While the benefits are immense, adopting digital twin technology in CNC machining isn’t without challenges:

- Initial investment costs can be high.

- Data security and privacy need robust protocols.

- Skilled workforce is required to interpret data and manage digital systems.

- Integration complexity with existing legacy machines and software.

However, the long-term ROI in terms of reduced downtime, improved quality, and faster production cycles can far outweigh these barriers.

The Future Outlook

The adoption of digital twin technology in CNC machining is expected to accelerate as the technology matures and becomes more accessible. Some trends to watch include:

- Wider adoption in small-to-medium enterprises (SMEs) through cloud-based solutions.

- Integration with AR/VR for immersive monitoring and training.

- Greater AI involvement for autonomous decision-making in machining operations.

- Sustainable manufacturing through energy and waste optimization.

In the future, CNC machining will not just be about cutting and shaping materials—it will be about intelligent orchestration, real-time learning, and continuous improvement driven by virtual insights.

Conclusion

The fusion of CNC machining and digital twin technology is redefining what’s possible in modern manufacturing. From enhancing accuracy and minimizing downtime to enabling predictive maintenance and data-driven decisions, this powerful combo is setting the stage for the next industrial leap.

Manufacturers who embrace digital twins today are not just improving their current operations—they’re future-proofing their business for a more agile, intelligent, and efficient tomorrow.

Explore More from Sahil Machines

Want to learn more about how digital twin technology can transform your CNC operations? Check out these insightful resources from Sahil Machines:

FAQ

Digital twin technology creates a real-time virtual replica of CNC machines, enabling precision control, predictive maintenance, and performance optimization.

By continuously collecting data from CNC machines, digital twins identify wear patterns and potential issues before they cause breakdowns, allowing for timely maintenance.

While the upfront investment may be significant, cloud-based and modular solutions are making it increasingly accessible and cost-effective for small and mid-sized manufacturers.

Yes, digital twins can simulate everything from tool paths and spindle speed to material behavior, allowing engineers to optimize the process virtually before actual production.

Digital twins integrate with IoT, AI, and cloud platforms to enable smarter, data-driven manufacturing aligned with Industry 4.0 standards.

Follow Us:

Latest Posts

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.