The Role of Data Analytics in CNC Production Planning and Workflow Optimization

Data analytics plays a critical role in optimizing CNC production planning and workflow. Learn how manufacturers are leveraging data to improve efficiency, reduce downtime, and streamline operations.

July 09, 2025

Share:

In today’s highly competitive manufacturing landscape, the need for efficiency, accuracy, and cost-effectiveness has never been more crucial. As manufacturers seek to stay ahead of the curve, data analytics has emerged as a powerful tool in CNC (Computer Numerical Control) machining, helping to optimize production planning and streamline workflow management. By harnessing the power of data, manufacturers can make smarter decisions, improve machine performance, and reduce downtime, all of which contribute to a more efficient and profitable production environment.

In this blog, we will explore how data analytics plays a vital role in CNC production planning, workflow optimization, and enhancing overall manufacturing efficiency.

Understanding Data Analytics in CNC Machining

Data analytics involves the process of collecting, processing, and analyzing large volumes of data to uncover patterns, trends, and insights that can inform decision-making. In CNC machining, data analytics involves the real-time collection of data from CNC machines, sensors, production processes, and enterprise systems. This data is then analyzed to improve operational performance and workflow efficiency.

Key data sources in CNC machining include:

- Machine sensors: These collect data on parameters such as temperature, vibration, pressure, and cutting force.

- Production schedules: Data on material inventory, machine availability, and production timelines.

- Operational logs: Historical data on machine performance, tool wear, and maintenance schedules.

- Quality control data: Information on the finished product’s dimensions, tolerances, and overall quality.

By analyzing this data, manufacturers can gain insights into every aspect of their production process, from planning to execution.

The Role of Data Analytics in CNC Production Planning

CNC production planning is a critical aspect of ensuring that machining operations are carried out in the most efficient and cost-effective way possible. Traditionally, production planning in CNC machining was based on historical experience, intuition, and manual scheduling. However, with the advent of data analytics, manufacturers can now rely on real-time data to drive more accurate and informed decisions.

1. Optimizing Resource Allocation

Data analytics helps in optimizing resource allocation by analyzing the availability of machines, operators, and materials. For example, predictive algorithms can determine which machines are likely to be idle based on historical usage data and upcoming schedules. This enables manufacturers to allocate resources more efficiently and reduce bottlenecks in the production process.

By analyzing data on tool usage and wear, manufacturers can also schedule tool changes or replacements in advance, preventing unexpected breakdowns or delays.

2. Demand Forecasting

One of the significant advantages of data analytics in CNC production planning is the ability to forecast demand and plan production accordingly. By analyzing historical production data, market trends, and customer demand, manufacturers can predict which products will be in high demand, and adjust production schedules and inventory levels to meet these needs. This helps to prevent overproduction or underproduction, reducing waste and improving resource efficiency.

3. Enhanced Scheduling

With the help of data analytics, CNC production schedules can be dynamically adjusted in real-time. Data-driven scheduling tools can consider factors such as machine availability, tool change times, setup times, and employee shifts. This allows manufacturers to create optimal schedules that minimize downtime, maximize machine usage, and ensure on-time delivery.

How Data Analytics Optimizes CNC Workflow

Once production planning is in place, the next step is ensuring that the workflow is optimized for maximum efficiency. Data analytics plays a vital role in streamlining workflows, reducing unnecessary steps, and ensuring that every aspect of the production process is running smoothly.

1. Real-Time Monitoring and Performance Tracking

By using data analytics tools, manufacturers can monitor the performance of CNC machines and operators in real-time. This data provides insight into machine utilization, cycle times, and overall equipment efficiency (OEE). By tracking these metrics, manufacturers can identify areas of improvement and make adjustments as needed.

For instance, if a machine is underperforming or taking longer to complete a task than expected, the data can pinpoint the root cause—whether it's a tool issue, operator inefficiency, or machine wear. With this information, corrective actions can be taken immediately, improving workflow and minimizing disruptions.

2. Predictive Maintenance

One of the most significant contributions of data analytics to CNC workflow optimization is predictive maintenance. Using data from machine sensors, manufacturers can predict when a machine is likely to require maintenance, reducing the likelihood of unexpected breakdowns. This allows for maintenance to be scheduled during non-productive hours, ensuring that production continues without interruption.

For example, by monitoring the vibration levels of a CNC spindle, data analytics can predict when the spindle is likely to fail, enabling maintenance personnel to replace or service the part before it causes downtime.

3. Process Optimization and Continuous Improvement

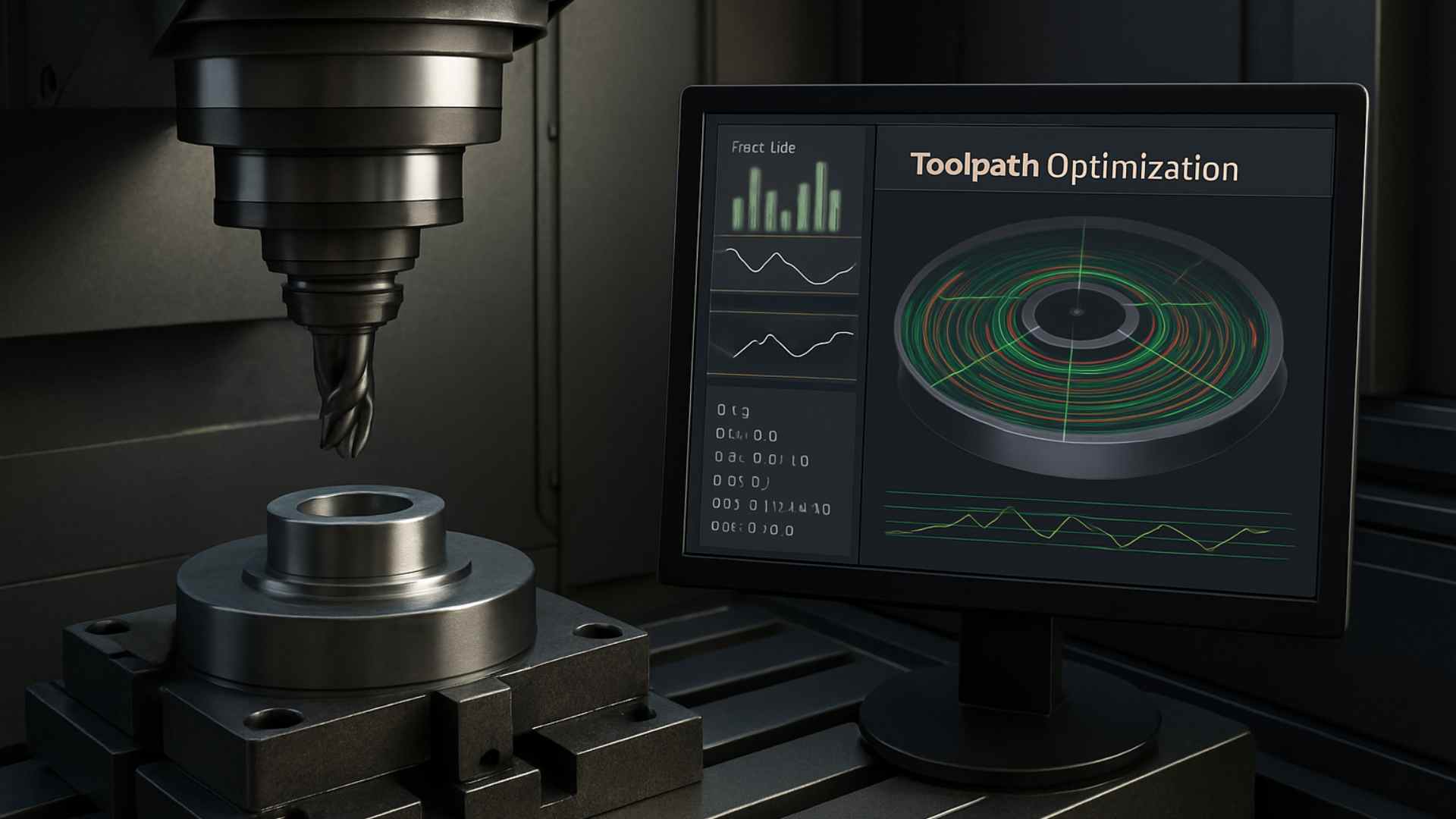

Data analytics also helps identify inefficiencies in the manufacturing process. By analyzing data from each stage of production, manufacturers can spot patterns that indicate inefficiencies, such as excessive cycle times, excessive tool wear, or frequent machine stoppages. With this data, manufacturers can implement process improvements, such as modifying machine settings, adjusting feed rates, or optimizing tool paths.

Furthermore, data analytics supports continuous improvement initiatives by providing a data-driven approach to Six Sigma or Lean Manufacturing. This approach allows manufacturers to make incremental improvements that gradually increase productivity while maintaining high-quality standards.

The Impact of Data Analytics on CNC Machine Performance

CNC machines are at the heart of any manufacturing process, and optimizing their performance is crucial to ensuring smooth operations. Data analytics plays a vital role in improving machine performance by providing deep insights into machine health, efficiency, and wear patterns.

1. Optimizing Cutting Parameters

By analyzing data from cutting operations, such as cutting forces, temperatures, and material behavior, manufacturers can fine-tune cutting parameters to improve tool life, surface finish, and overall machining efficiency. Data analytics enables manufacturers to optimize parameters such as feed rates, cutting speeds, and depths of cut, reducing tool wear and increasing the accuracy of the finished product.

2. Monitoring Machine Health

Data analytics allows for continuous monitoring of machine health by tracking key performance indicators (KPIs) such as vibration, temperature, and power consumption. By identifying abnormal patterns in this data, manufacturers can detect issues early and prevent costly machine failures. Predictive algorithms can assess the likelihood of a breakdown, giving operators ample time to address potential issues before they result in unplanned downtime.

Conclusion

Data analytics is revolutionizing the way CNC machining operations are planned, optimized, and executed. By leveraging data-driven insights, manufacturers can make smarter decisions, optimize workflows, enhance machine performance, and significantly reduce downtime. As the manufacturing industry continues to evolve, embracing data analytics will be critical to staying competitive, improving operational efficiency, and achieving long-term success.

Explore More from Sahil Machines

FAQ

Data analytics helps optimize resource allocation, forecast demand, and improve scheduling, allowing manufacturers to make data-driven decisions that lead to more efficient production planning.

Predictive maintenance, powered by data analytics, helps anticipate machine failures before they occur. By monitoring machine health and performance, manufacturers can schedule maintenance at the most opportune time, reducing downtime and extending machine life.

By analyzing real-time data from CNC machines, manufacturers can optimize cutting parameters, monitor machine health, and fine-tune machine settings to improve efficiency, reduce wear, and enhance product quality.

Data analytics helps streamline CNC workflows by providing real-time performance tracking, identifying inefficiencies, and facilitating continuous improvement through data-driven decisions.

Manufacturers can implement data analytics by integrating sensors, monitoring tools, and analytics platforms that collect and analyze machine data to make informed decisions about production planning, machine maintenance, and process optimization.

Follow Us:

Latest Posts

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.