CNC Machining in Railways: Why It’s Crucial for Infrastructure Growth

Introduction The railway industry is undergoing a major transformation, with precision engineering and automation playing a pivotal role in infrastructure growth. CNC machining is revolutionizing railway manufacturing by improving efficiency, safety, and sustainability. As global railway networks expand, CNC technology is becoming indispensable for producing high-quality components with unparalleled accuracy.

-

The Role of CNC Machining in Railways Rail transport demands precision-engineered parts for optimal performance and durability. CNC machining enables the production of complex railway components with high accuracy, ensuring smoother operations and reduced maintenance costs. Key CNC Applications in Railways: Axle & Wheel Manufacturing – Precision CNC turning ensures perfectly balanced axles and wheels, enhancing safety and performance. Bogie Components & Chassis Parts – High-strength bogies are machined to withstand extreme loads and dynamic forces. Railway Track Machining – CNC milling is used for rail profiling, ensuring tracks are manufactured to exact specifications. Locomotive & Engine Parts – Critical engine components are CNC-milled for enhanced efficiency and fuel savings.

-

Automation & Smart Manufacturing in Railway CNC With railway networks expanding rapidly, automation in CNC machining is crucial for meeting growing demand. Smart factories equipped with CNC automation are streamlining production while reducing lead times. Benefits of Automated CNC in Railways: Faster Manufacturing & Scalability – Reduced cycle times ensure timely project completion. Precision & Consistency – Advanced CNC systems eliminate human errors. Predictive Maintenance – IoT-enabled CNC machines prevent downtime through real-time diagnostics.

-

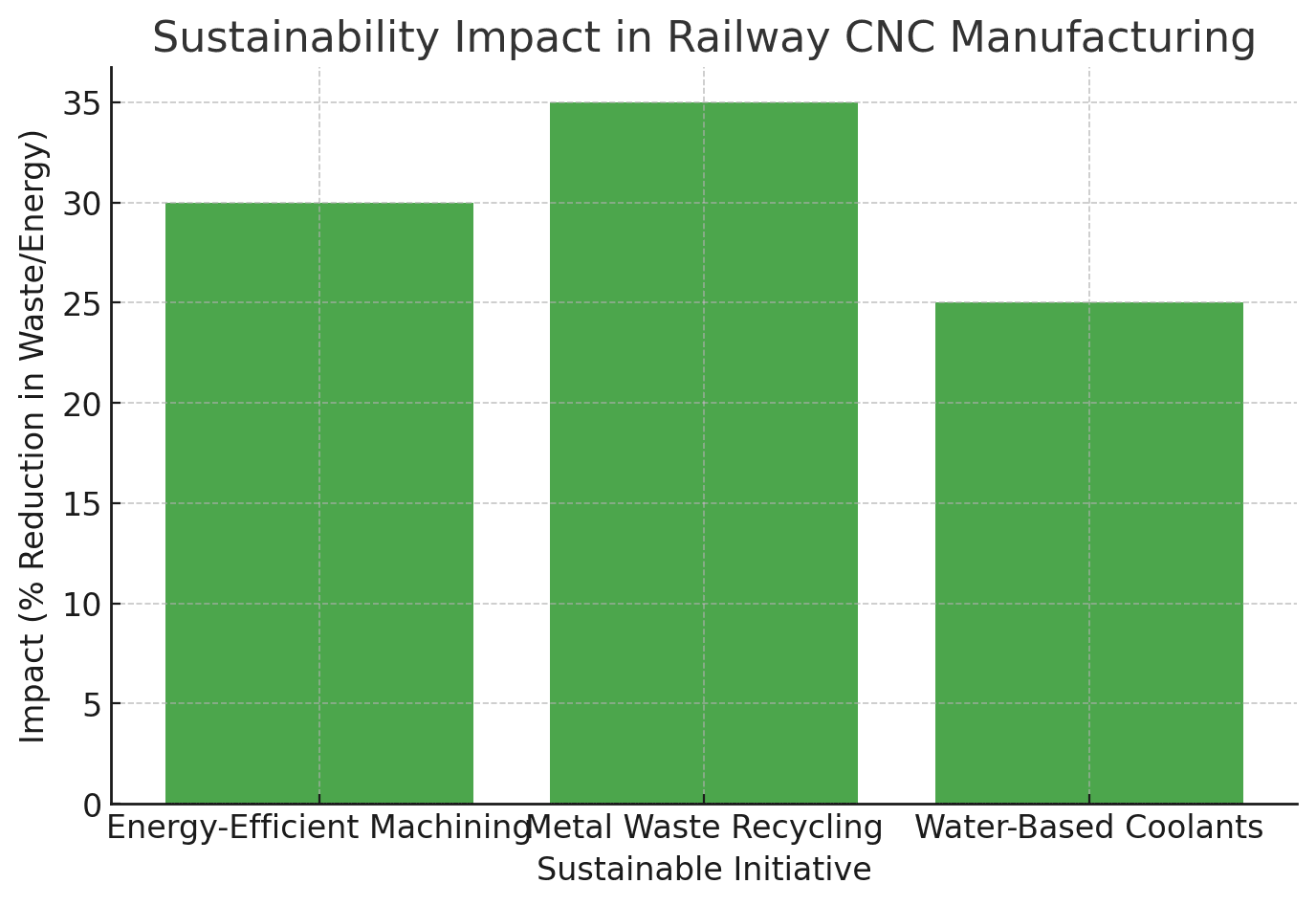

Sustainability in Railway CNC Manufacturing Eco-friendly production is a top priority for modern rail infrastructure. CNC machining supports sustainability by minimizing waste and optimizing resource utilization. Sustainable CNC Innovations: Energy-Efficient Machining – New-generation CNC machines cut energy consumption by up to 30%. Recycling of Metal Waste – CNC machining enables the reuse of metal chips, reducing raw material costs. Water-Based Coolants – These minimize the environmental impact of chemical-based lubricants.

-

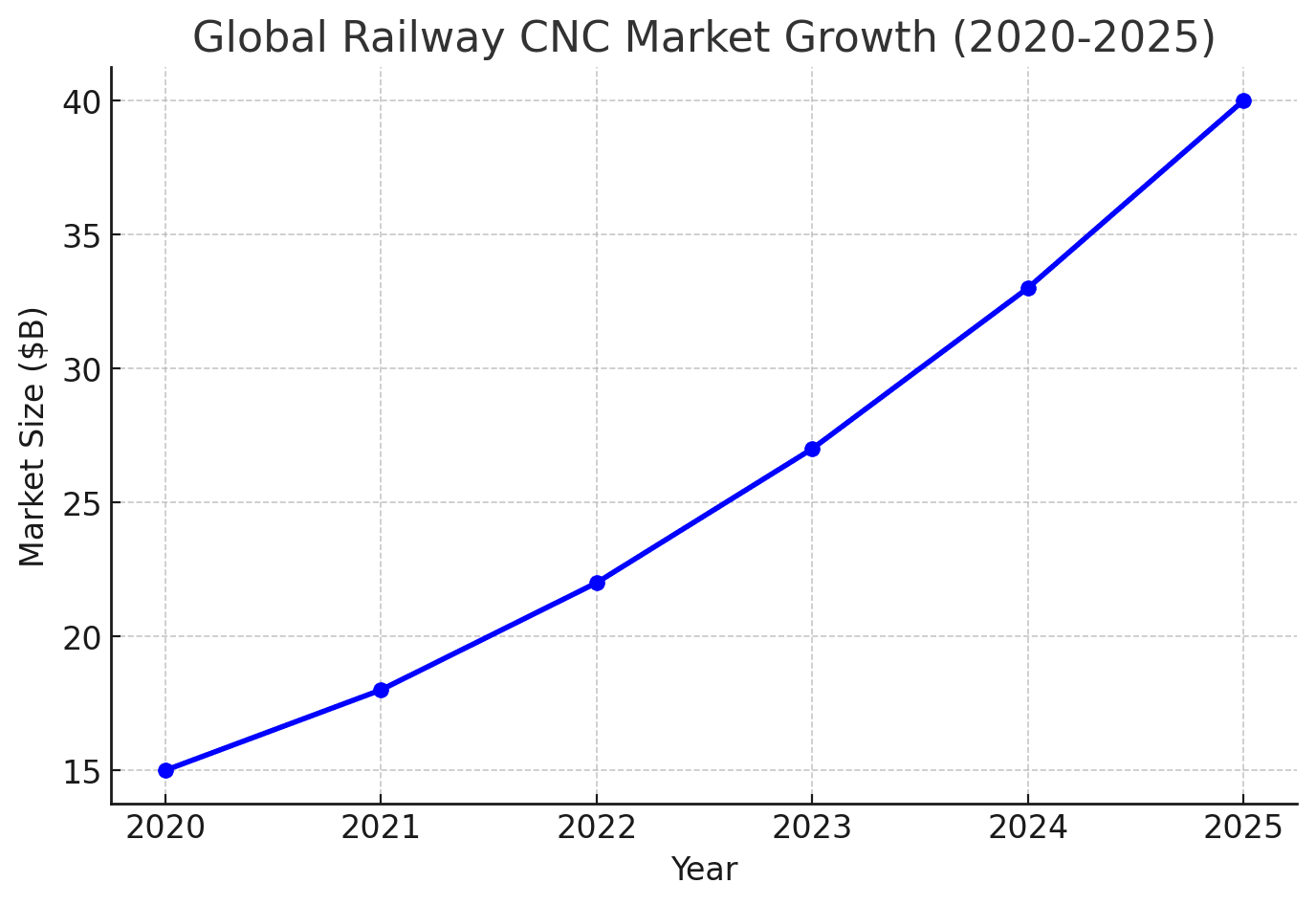

Global Growth & Investment in Railway CNC Countries worldwide are investing heavily in railway infrastructure, driving demand for CNC machining solutions. Nations like India, China, and the U.S. are leading the way with high-speed rail projects, increasing the need for precision-engineered components. Why Railways Are Investing in CNC Machining: Improved Reliability & Safety – CNC ensures strict compliance with global railway safety standards. Lower Maintenance Costs – Precision manufacturing reduces wear and tear. Government Policies Favoring Railway Expansion – Infrastructure funding is fueling CNC-driven railway production.

Conclusion CNC machining is shaping the future of railway infrastructure with unparalleled precision, automation, and sustainability. As railway networks expand globally, CNC technology will remain at the heart of manufacturing efficiency, ensuring high-quality and cost-effective production. Sahil Machines is driving this transformation with state-of-the-art CNC solutions for the railway industry. Visit us:www.sahilcnc.com Inquiries: info@sahilcnc.com Follow Sahil Machines for the latest CNC industry insights!

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.