Future Demand for CNC Machines in the Middle East & Africa: Key Growth Drivers & Opportunities

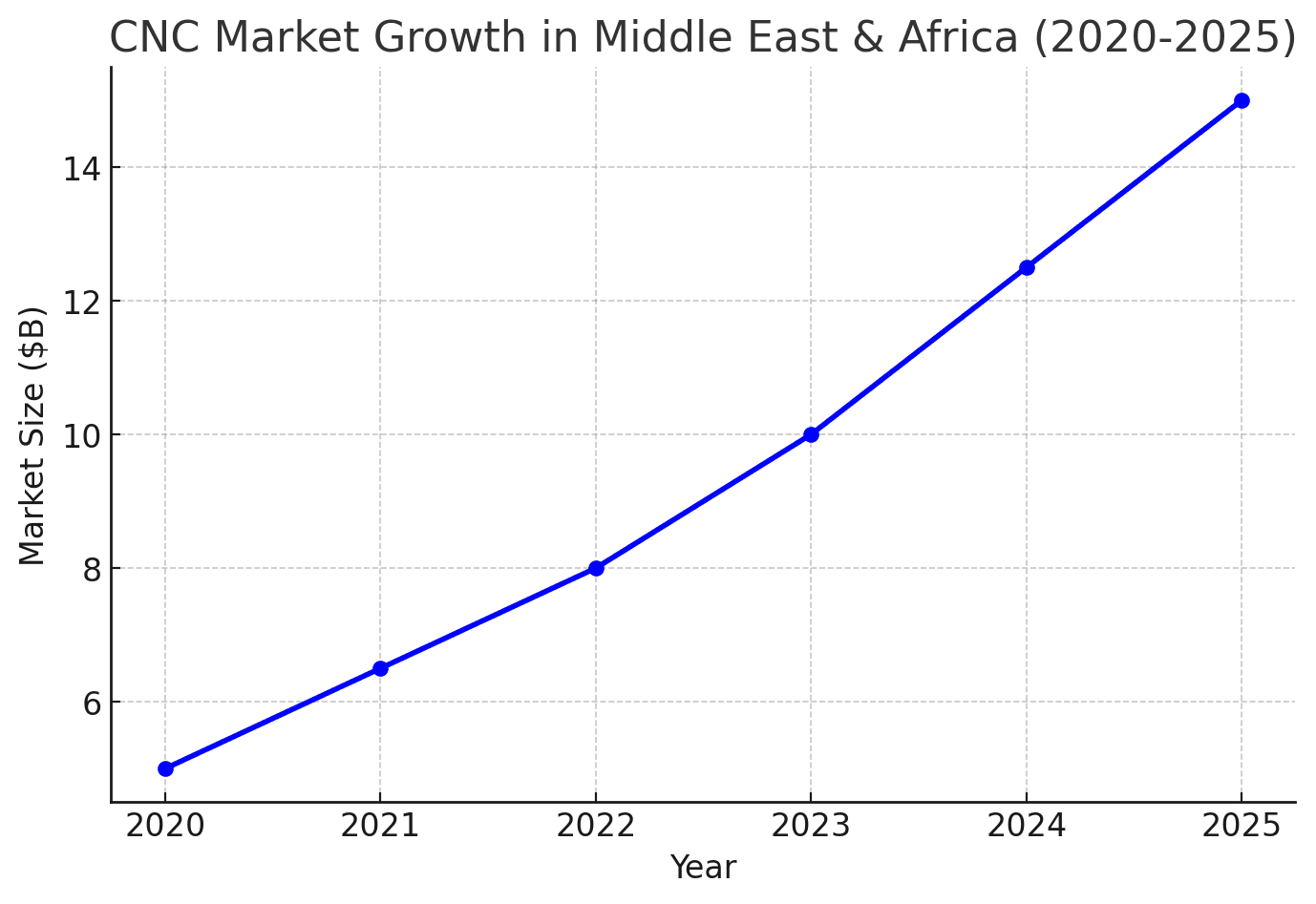

Introduction The CNC (Computer Numerical Control) machining industry is witnessing rapid expansion worldwide, and the Middle East & Africa (MEA) region is no exception. With industrial growth, rising foreign investments, and a strong push towards automation, the demand for CNC machines is expected to surge in MEA over the next decade.

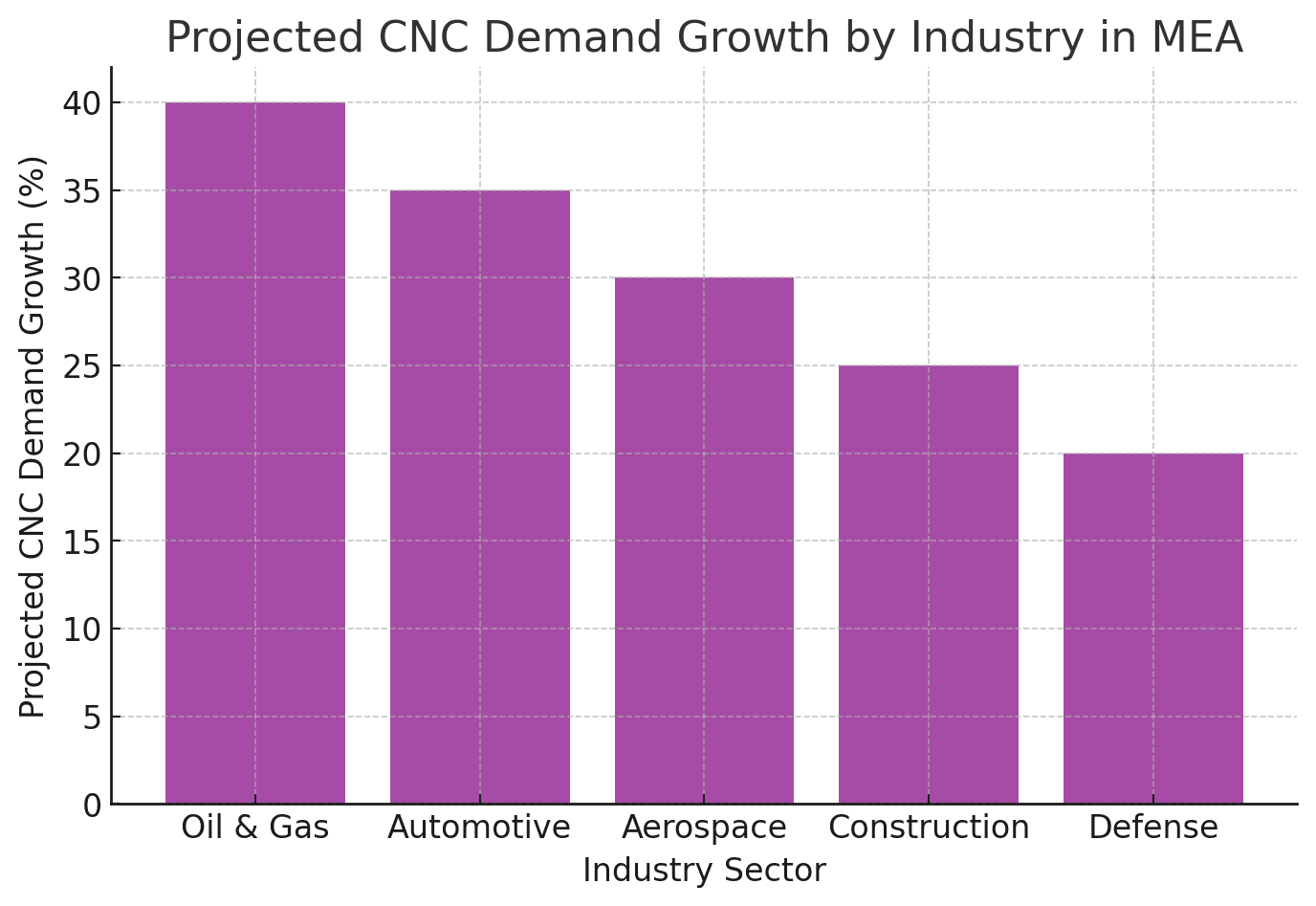

- Infrastructure & Industrial Expansion Fueling CNC Growth The Middle East and Africa are experiencing unprecedented industrialization, with governments and private investors focusing on expanding manufacturing, construction, and defense industries. Key Factors Driving Growth: Government Initiatives: Countries like Saudi Arabia, the UAE, and Egypt are investing heavily in industrialization under programs like Vision 2030. Booming Construction Sector: CNC machines are widely used in metal fabrication for large-scale infrastructure projects. Automotive & Aerospace Investments: Major automotive brands are setting up plants in Egypt and South Africa, increasing demand for CNC machining.

-

Adoption of Multi-Axis CNC & Advanced Machining Technologies Traditional CNC machines are making way for multi-axis, high-speed, and AI-powered CNC systems, helping industries achieve precision and efficiency. Why Multi-Axis CNC is in High Demand? Enhanced Precision & Faster Production – Essential for aerospace, automotive, and oil & gas industries. Lower Material Wastage – Reducing costs and improving sustainability. Growing Demand for Custom Manufacturing – Rapid prototyping and mass customization are boosting CNC adoption.

-

Oil & Gas Industry Driving Demand for Heavy-Duty CNC Machines The Middle East remains the global leader in oil & gas production. With an increasing focus on refinery expansion, pipeline manufacturing, and precision engineering, the demand for CNC machines capable of handling large components is set to rise. CNC Applications in Oil & Gas: Drilling Equipment Manufacturing – CNC lathe and boring machines are essential for precision machining. Pipeline & Valve Production – High-accuracy CNC machining ensures long-lasting components. Component Refurbishment – CNC milling and grinding improve equipment longevity and performance.

-

Automation & Smart CNC Machines: The Future of Manufacturing Industries in MEA are transitioning towards lights-out manufacturing (fully automated CNC machining with minimal human intervention). Key Benefits of CNC Automation in MEA: 24/7 Manufacturing with High Output – Ensuring large-scale production with minimal downtime. IoT-Enabled CNC Machines – Real-time monitoring and predictive maintenance reduce operational costs. Smart Factories Integration – AI-driven CNC technology enhances production efficiency.

-

Rising Demand in Emerging Markets: South Africa, Egypt & Nigeria The growth of local manufacturing, defense, and industrial sectors in key African nations is significantly boosting CNC demand. Market Trends: South Africa – Focus on precision engineering and manufacturing. Egypt – Rapid industrialization and increased government incentives. Nigeria – Expansion in the oil, gas, and mining industries.

-

Challenges & Opportunities for CNC Manufacturers in MEA While the CNC market in MEA is poised for growth, some challenges remain. High import duties on machinery, lack of skilled operators, and supply chain disruptions can affect the speed of adoption. How Manufacturers Can Overcome These Challenges: Localization of CNC Production – Setting up local manufacturing hubs. Skill Development Programs – Training CNC operators for advanced machining. Leveraging Government Subsidies – Taking advantage of industrial automation incentives. Conclusion The future of CNC machining in the Middle East & Africa looks promising, with automation, industrial expansion, and heavy investments in key sectors driving demand. Manufacturers that adopt advanced CNC solutions and cater to the region’s growing needs will gain a competitive edge. Sahil Machines is actively supporting CNC advancements in MEA with cutting-edge, high-precision solutions. Visit us:www.sahilcnc.com Inquiries:info@sahilcnc.com Follow Sahil Machines for the latest CNC industry trends!

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.