How CNC Automation Can Reduce Production Costs

Introduction In an era where manufacturing efficiency determines success, CNC automation has emerged as a game-changer. By integrating advanced robotics, AI-driven control systems, and real-time monitoring, businesses can significantly reduce production costs while enhancing quality and scalability.

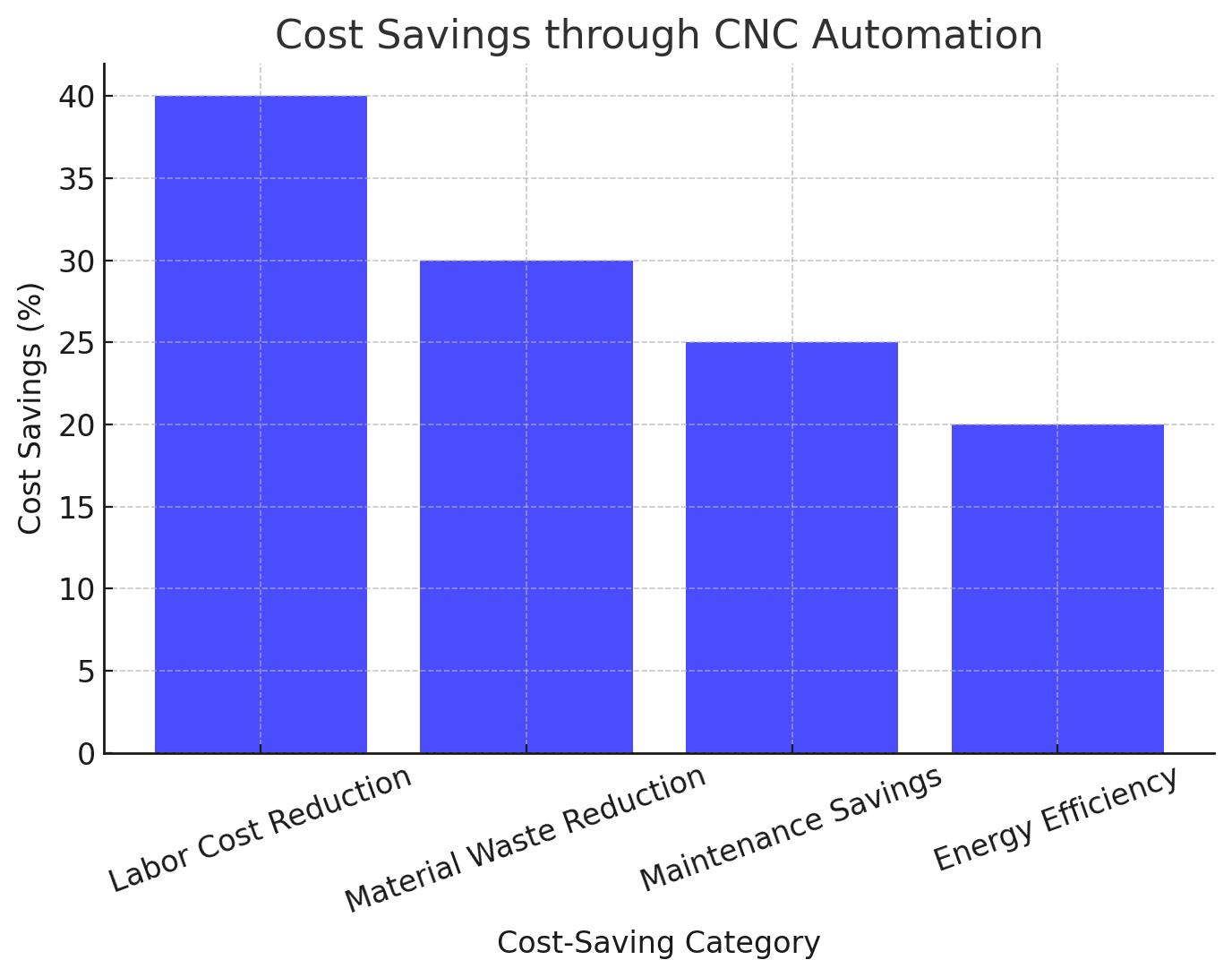

- Lower Labor Costs & Minimal Human Intervention Traditional CNC operations require skilled labor for setup, supervision, and adjustments. With CNC automation, manufacturers can achieve lights-out manufacturing—fully autonomous operations with minimal human oversight. Key Benefits: 24/7 production with reduced manpower Lower operational costs due to fewer manual interventions Enhanced safety with minimal human-machine interaction

-

Reduced Material Waste with Precision Machining Automated CNC systems ensure high-precision machining, minimizing errors and material wastage. AI-powered toolpath optimization helps in utilizing raw materials efficiently, reducing scrap rates by up to 30%. Why This Matters? More parts produced per raw material unit Less material wastage means lower procurement costs Consistent quality output with fewer defects

-

Predictive Maintenance for Lower Downtime Unexpected machine failures can cause production delays and financial losses. IoT-enabled CNC machines monitor real-time performance and predict potential failures before they occur, ensuring proactive maintenance. Cost-Saving Impact: Prevents sudden breakdowns and expensive repairs Extends the lifespan of CNC equipment Reduces production stoppages and delivery delays

-

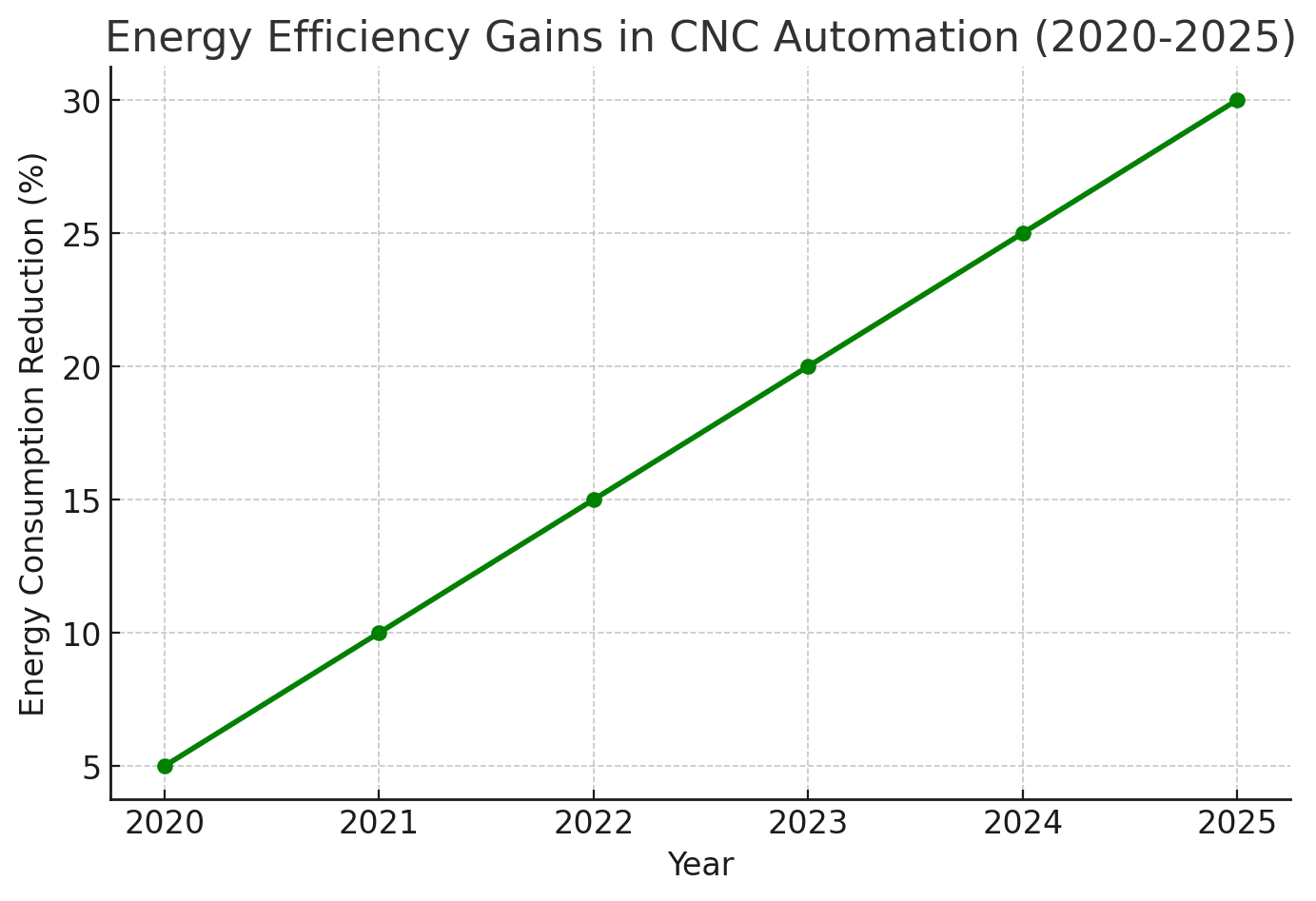

Energy-Efficient With rising energy costs, manufacturers are shifting to energy-efficient motors and AI-driven power optimization for CNC machines. These smart systems adjust energy consumption based on workload, cutting electricity costs significantly. Energy-Saving Features: Smart power regulation lowers consumption by 20-30% Energy-efficient motors reduce electricity bills Sustainable machining with optimized cooling & lubrication

-

Higher Productivity & Faster Turnaround Times CNC automation speeds up production cycles by eliminating manual repositioning and reducing setup times. Multi-axis CNC machining further enhances efficiency by enabling complex operations in a single setup. Productivity Gains: Faster machining with automated tool changes Increased output without expanding workforce Quicker turnaround for high-volume production Conclusion CNC automation is not just a technological advancement—it’s a strategic investment for manufacturers looking to cut costs and scale operations. By reducing labor dependency, minimizing waste, and optimizing energy use, CNC automation is revolutionizing cost-effective production. Sahil Machines is at the forefront of CNC automation, delivering high-precision, energy-efficient solutions for global industries. Visit us:www.sahilcnc.com Inquiries:info@sahilcnc.com Follow Sahil Machines for the latest CNC industry updates!

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.