How CNC Machines Are Revolutionizing the Automotive Industry

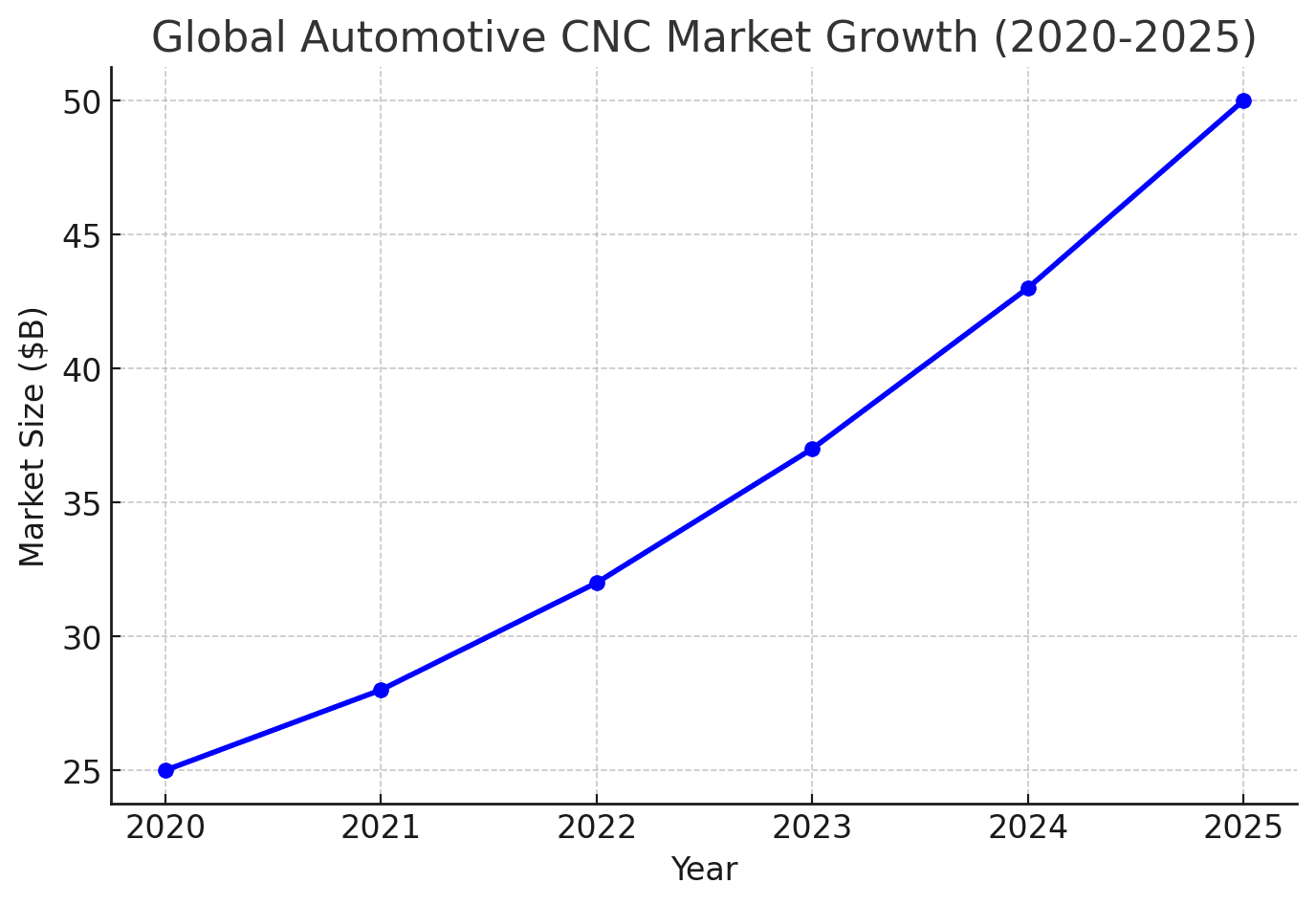

The automotive industry is undergoing a technological transformation, and CNC (Computer Numerical Control) machines are at the forefront of this evolution. With advancements in automation, precision engineering, and material optimization, CNC machining is playing a crucial role in revolutionizing vehicle manufacturing. From engine components to chassis parts, automakers are leveraging CNC technology to enhance efficiency, reduce waste, and improve performance.

-

Unmatched Precision & Quality in Automotive Components Modern automobiles demand high levels of precision, and CNC machining delivers unparalleled accuracy in manufacturing intricate vehicle parts. Key Benefits: Micron-level precision: Essential for engine components, transmission parts, and safety-critical systems. Improved consistency: CNC automation ensures uniformity in mass production. Reduced human error: Computerized control minimizes deviations and defects.

-

Acceleration of Electric Vehicle (EV) Manufacturing The shift towards electric vehicles (EVs) is driving new demands in machining technology. CNC machines are instrumental in producing lightweight yet durable components essential for EV efficiency. CNC’s Role in EV Production: Manufacturing lightweight aluminum parts to increase energy efficiency. Precision-cut battery casings for optimal safety and longevity. Customization of complex motor components required for EV propulsion systems.

-

CNC Automation & Lights-Out Manufacturing in Automotive Plants Automation is transforming automotive manufacturing with lights-out machining—where CNC machines run autonomously with minimal human supervision, boosting productivity and efficiency. How Automation is Reshaping the Industry: 24/7 operation reducing production times and costs. Robotic integration improving material handling and assembly. AI-powered predictive maintenance preventing downtime and optimizing performance.

-

Hybrid Manufacturing: CNC + 3D Printing Hybrid manufacturing is merging CNC machining with additive manufacturing (3D printing) to enhance prototyping and reduce material waste. Key Advantages: 50% reduction in material waste with optimized subtractive machining. Rapid prototyping enabling faster automotive innovation. Stronger & lightweight composite structures for fuel efficiency.

-

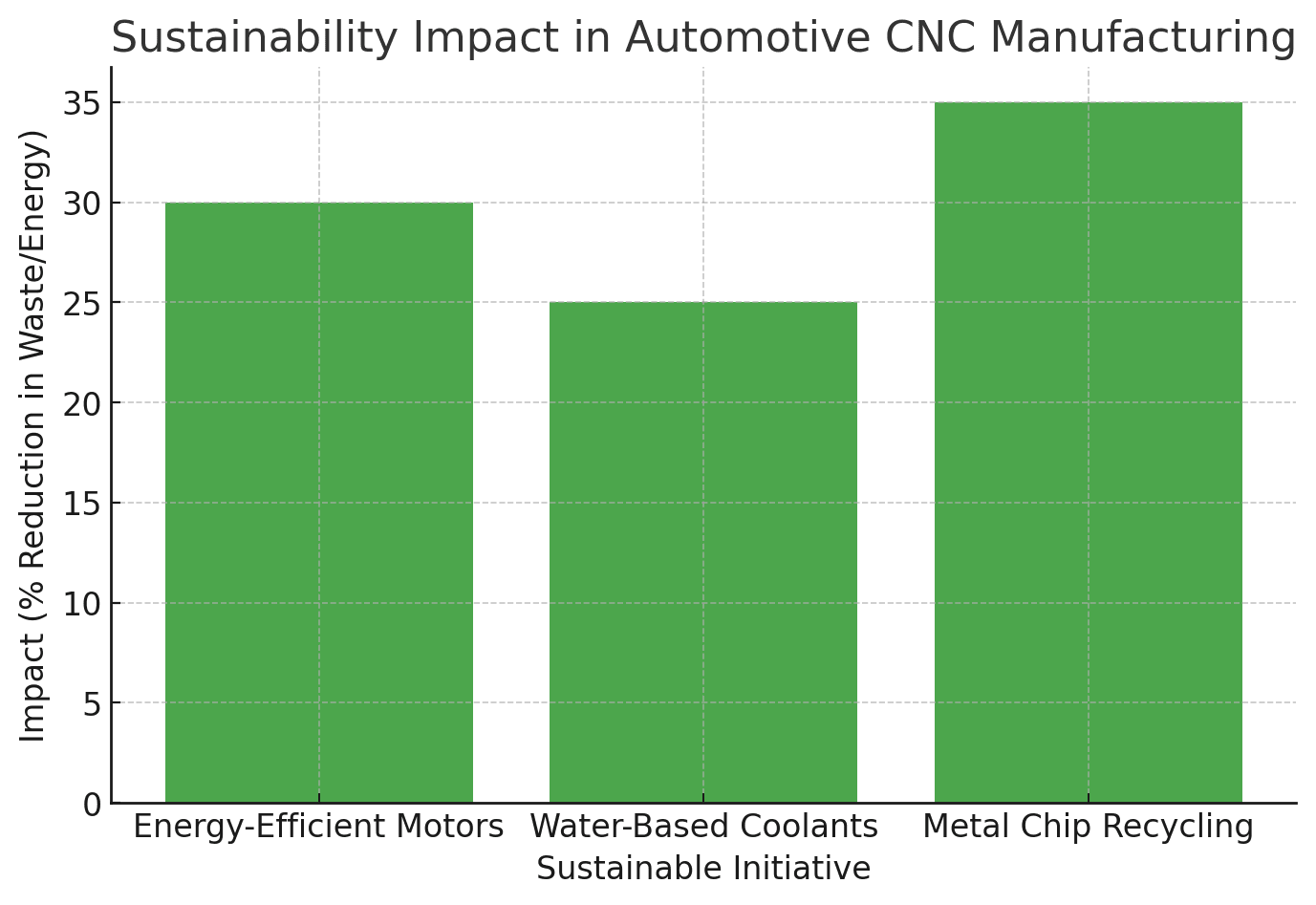

Sustainable CNC Practices in Automotive Production The push for sustainability is encouraging automakers to adopt eco-friendly CNC machining techniques that minimize environmental impact. Sustainable CNC Trends: Energy-efficient motors cutting power consumption by 20-30%. Water-based coolants reducing harmful chemical waste. Metal chip recycling lowering production costs and waste.

-

CNC Technology in Emerging Automotive Markets Countries like India, Vietnam, and Brazil are becoming major hubs for CNC-driven automotive manufacturing, thanks to government incentives and industrial expansion. Growth Drivers: Lower operational costs making manufacturing more competitive. Investment in smart factories integrating CNC with Industry 4.0. Growing demand for precision automotive parts fueling CNC adoption.

-

Advancements in CNC Software & AI-Driven Machining AI and cloud-based CNC software are transforming how automotive manufacturers optimize production. Latest Innovations: AI-powered simulations reducing trial-and-error in manufacturing. Cloud-based CNC software enabling real-time monitoring & remote control. Automated toolpath optimization increasing machining speed and accuracy.

Conclusion CNC machining is at the heart of the automotive industry’s future, enabling greater efficiency, precision, and sustainability. As automakers shift towards EVs, smart factories, and sustainable practices, CNC technology will continue to drive innovation and competitiveness. Sahil Machines is leading the CNC revolution in the automotive sector, providing cutting-edge machining solutions for global manufacturers. Visit us: www.sahilcnc.com Inquiries: info@sahilcnc.com Follow Sahil Machines for the latest CNC industry insights!

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.