How Preventive Maintenance Can Reduce CNC Machine Downtime

Introduction CNC machines are the backbone of modern manufacturing, providing precision, efficiency, and high-speed production. However, unexpected breakdowns can disrupt production schedules, increase costs, and lead to significant losses. Implementing a preventive maintenance strategy can significantly reduce CNC machine downtime, ensuring seamless operations and prolonged equipment life.

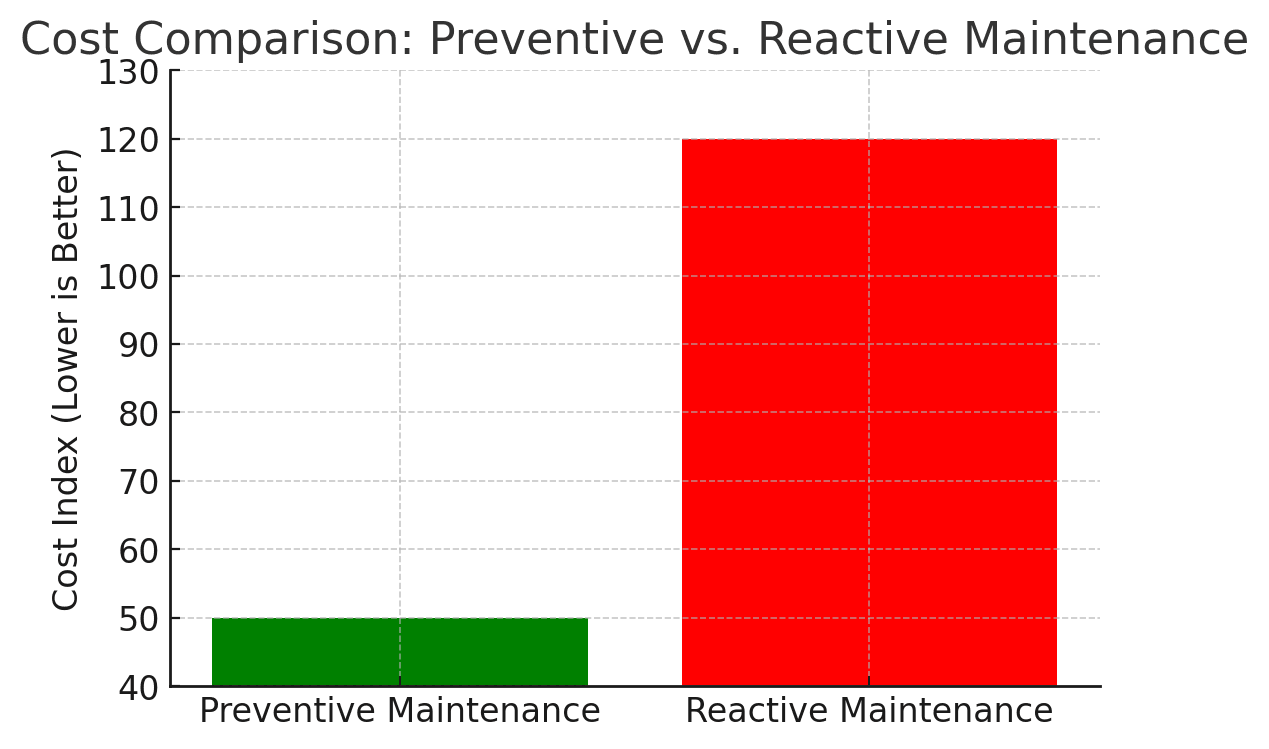

What is Preventive Maintenance in CNC Machining? Preventive maintenance (PM) involves regularly scheduled inspections, servicing, and repairs to prevent unexpected failures. Unlike reactive maintenance, which addresses issues after they occur, preventive maintenance proactively identifies and resolves potential problems before they lead to machine breakdowns.

Key Benefits of Preventive Maintenance Minimized Downtime – Regular inspections and servicing reduce unexpected breakdowns, keeping production running smoothly. Extended Machine Lifespan – Proper maintenance prevents excessive wear and tear, prolonging the service life of CNC machines. Improved Productivity & Efficiency – Well-maintained machines operate at optimal efficiency, reducing errors and ensuring high-quality output. Cost Savings on Repairs – Preventive maintenance helps avoid costly emergency repairs and unplanned machine replacements. Enhanced Safety – Addressing potential hazards early ensures a safer work environment for operators. Essential Preventive Maintenance Practices

- Daily Inspection & Cleaning •Remove chips and debris to prevent overheating and machine damage. •Check lubrication levels to ensure smooth operation. •Inspect tools for signs of wear and replace them as needed.

- Weekly & Monthly Maintenance Checks •Inspect coolant levels and replace if necessary to maintain optimal temperature control. •Test spindle and bearing conditions to avoid vibration issues. •Examine electrical connections and sensors for any faults.

- Quarterly & Annual Maintenance •Conduct a full diagnostic check of machine performance. •Replace worn-out belts, hoses, and filters. •Recalibrate axes and tool offsets to maintain precision.

Role of IoT & AI in Predictive CNC Maintenance Modern CNC machines are integrating IoT (Internet of Things) sensors and AI-driven predictive analytics to enhance preventive maintenance: Real-time Monitoring – IoT-enabled sensors track machine performance, alerting operators to potential issues before failure occurs. Predictive Maintenance – AI analyzes historical data to predict when components will need maintenance, reducing unexpected downtime. Remote Diagnostics – Cloud-based software allows manufacturers to monitor machine health from anywhere, enabling faster decision-making.

How Sahil Machines Ensures CNC Reliability with Preventive Maintenance At Sahil Machines, we understand the critical role preventive maintenance plays in CNC machining. Our advanced CNC solutions come equipped with: Smart Diagnostic Systems – Integrated sensors detect and report performance anomalies in real time. User-Friendly Maintenance Schedules – Custom maintenance plans tailored to specific CNC machine models and usage patterns. 24/7 Support & Service Assistance – Our expert team ensures your machines stay operational with minimal disruptions.

Conclusion Preventive maintenance is no longer optional but a necessity in modern CNC machining. By adopting proactive maintenance strategies, manufacturers can minimize downtime, improve productivity, and extend the lifespan of their CNC machines. Sahil Machines is committed to delivering high-performance CNC solutions that keep industries running efficiently. Visit us: www.sahilcnc.com Inquiries: info@sahilcnc.com Follow Sahil Machines for the latest CNC industry insights!

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.