How to Choose the Right CNC Machine for Your Industry

Introduction CNC (Computer Numerical Control) machines have revolutionized modern manufacturing, offering unparalleled precision, efficiency, and automation. However, selecting the right CNC machine depends on several factors, including industry requirements, material compatibility, and production volume. In this guide, we break down the key considerations to help you choose the ideal CNC machine for your industry.

- Understand Your Industry’s CNC Needs Different industries have unique machining requirements. Choosing the right CNC machine depends on the type of components being produced and the level of precision needed.

- Aerospace & Defense – Requires high-precision 5-axis CNC machines for complex geometries and lightweight materials like titanium and composites.

- Automotive – Demands multi-axis CNC lathes and milling machines for producing high-volume precision parts.

- Medical & Healthcare – Prefers ultra-precise CNC milling and Swiss-type lathes for surgical instruments and implants.

- Oil & Gas – Uses heavy-duty CNC lathes for machining large, durable components.

- General Engineering & Tooling – Benefits from 3-axis and 4-axis machining centers for versatile part production.

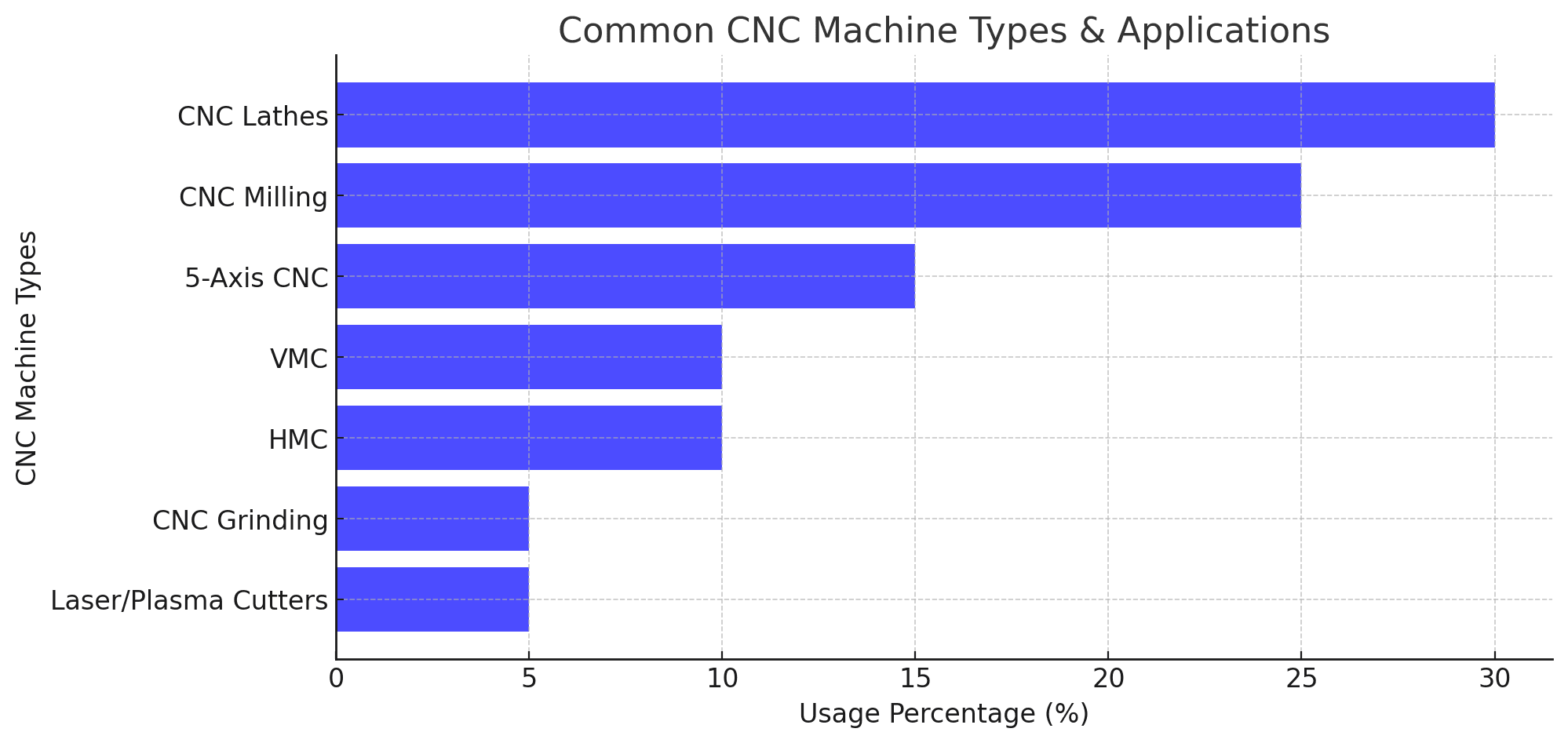

- Select the Right Type of CNC Machine Choosing between different types of CNC machines depends on the nature of your production process.

- CNC Lathes & Turning Centers – Ideal for cylindrical parts, shafts, and components requiring rotational symmetry.

- CNC Milling Machines – Best for complex, multi-surface machining with precise cutting and drilling.

- 5-Axis CNC Machines – Suitable for high-precision, multi-angled machining in aerospace, medical, and high-tech industries.

- CNC Vertical Machining Centers (VMC) – Great for general machining and part customization.

- CNC Horizontal Machining Centers (HMC) – Designed for high-speed production and bulk manufacturing.

- CNC Grinding Machines – Used for achieving fine surface finishes and tight tolerances.

- CNC Laser & Plasma Cutters – Preferred for sheet metal and high-speed cutting applications.

- Consider Machine Size & Work Envelope The size of the CNC machine should match your production needs.

- Small to Medium-Sized Parts – Compact CNC machines offer cost-effective production.

- Large Components & Heavy-Duty Machining – Gantry-style, double-column, and large-bed CNC machines are required for industrial applications.

- Look at Automation & Smart Features CNC automation is key for improving efficiency and reducing operational costs.

- Lights-Out Manufacturing – Fully automated CNC machines can run 24/7 with minimal human intervention.

- IoT-Enabled CNC Machines – Smart CNC machines with real-time monitoring and predictive maintenance enhance productivity.

- Robotic Integration – Automated loading and unloading systems reduce downtime and labor costs.

- Material Compatibility The material being processed plays a critical role in machine selection.

- Metals – CNC lathes and milling machines are ideal for steel, aluminum, titanium, and brass.

- Plastics & Composites – High-speed milling machines prevent material damage.

- Wood & Foam – CNC routers are best suited for precise cutting and shaping.

- Evaluate CNC Software & Programming Capabilities Modern CNC machines come with advanced software for better efficiency and precision.

- AI-Driven Simulations – Reduce errors and improve machining accuracy.

- Cloud-Based CNC Programming – Enables remote access and operation.

- Digital Twin Technology – Creates virtual replicas for optimizing CNC machining before actual production.

- Budget & Return on Investment (ROI) Consider the long-term ROI rather than just the upfront cost.

- Entry-Level CNC Machines – Suitable for small businesses and workshops.

- Mid-Range Machines – Ideal for moderate production needs.

- High-End Industrial Machines – Required for mass production and precision machining.

Conclusion Choosing the right CNC machine is essential for maximizing efficiency, precision, and profitability in manufacturing. By evaluating industry-specific needs, machine type, automation, material compatibility, and budget, businesses can make an informed decision.

- Sahil Machines provides high-performance CNC solutions for industries worldwide.

- Visit us: www.sahilcnc.com

- Inquiries: info@sahilcnc.com

- Follow Sahil Machines for CNC industry updates!

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.