Material Selection in CNC Machining: Steel, Aluminum, and More

Introduction CNC machining plays a vital role in manufacturing, offering precision and efficiency for industries such as aerospace, automotive, medical, and heavy engineering. One of the most crucial aspects of CNC machining is material selection, as it directly impacts durability, cost, machining efficiency, and final product quality. In this article, we explore the most commonly used CNC machining materials—steel, aluminum, titanium, and plastics—and their applications.

- Steel: Strength & Durability for Heavy-Duty Applications Steel is one of the most widely used materials in CNC machining due to its exceptional strength, wear resistance, and versatility. Why Choose Steel? High tensile strength for structural components Excellent durability and wear resistance Suitable for automotive, aerospace, and industrial machinery Popular Steel Types: •Mild Steel (1018, 1045): Cost-effective, easy to machine, used for general-purpose parts. •Stainless Steel (304, 316, 410): Corrosion-resistant, ideal for medical and food industry components. Tool Steel (D2, O1, A2): Extremely hard, used for cutting tools and dies.

-

Aluminum: Lightweight & High-Speed Machining Aluminum is widely favored in CNC machining due to its lightweight nature, excellent machinability, and corrosion resistance. Why Choose Aluminum? Lightweight yet strong, ideal for aerospace and automotive parts Corrosion-resistant, reducing maintenance costs Faster machining speeds, improving production efficiency Popular Aluminum Grades: •Aluminum 6061: High strength-to-weight ratio, used in structural components. •Aluminum 7075: Superior strength, commonly used in aerospace applications. •Aluminum 2024: Excellent fatigue resistance, suitable for aircraft structures.

-

Titanium: The Premium Choice for High-Performance Parts Titanium offers an unmatched combination of strength, corrosion resistance, and lightweight properties, making it ideal for critical applications. Why Choose Titanium? Outstanding strength-to-weight ratio for aerospace and defense Biocompatible, ideal for medical implants and surgical tools Corrosion and heat-resistant for extreme environments Popular Titanium Grades: •Titanium Grade 2: Good corrosion resistance, used for chemical processing equipment. Titanium Grade 5 (Ti-6Al-4V): High strength, commonly used in aerospace and medical implants.

- Plastics: Cost-Effective & Versatile for Prototyping Plastics are extensively used in CNC machining for lightweight, cost-effective, and chemically resistant components. Why Choose Plastics? Easy to machine, reducing manufacturing costs Non-conductive and chemical-resistant, suitable for electrical and medical industries Lightweight, making it ideal for portable devices Popular Plastic Materials: •ABS: High impact resistance, used in consumer electronics and automotive parts. •Nylon: Durable and wear-resistant, ideal for gears and mechanical components. •POM (Delrin): Low friction, excellent for precision mechanical parts.

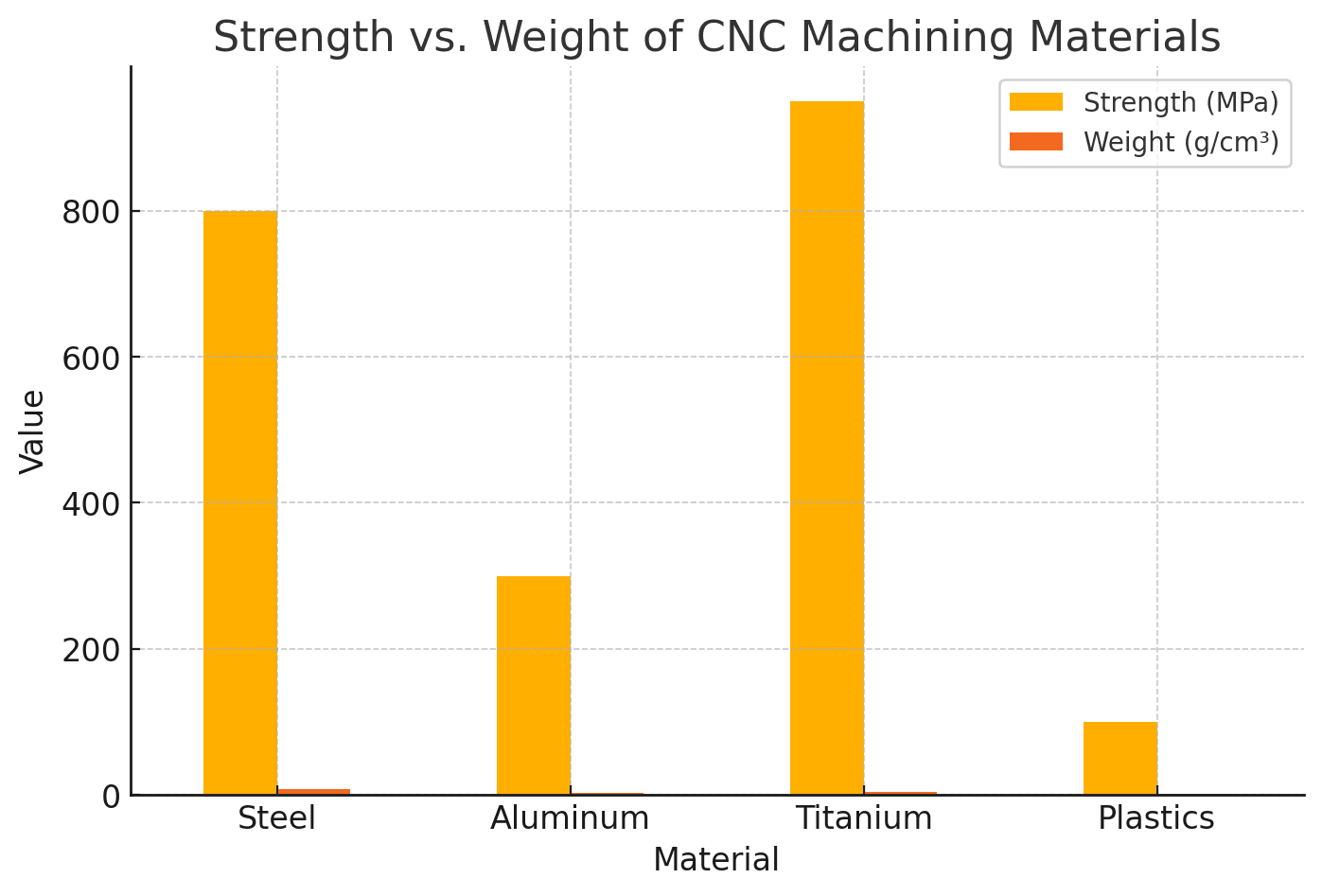

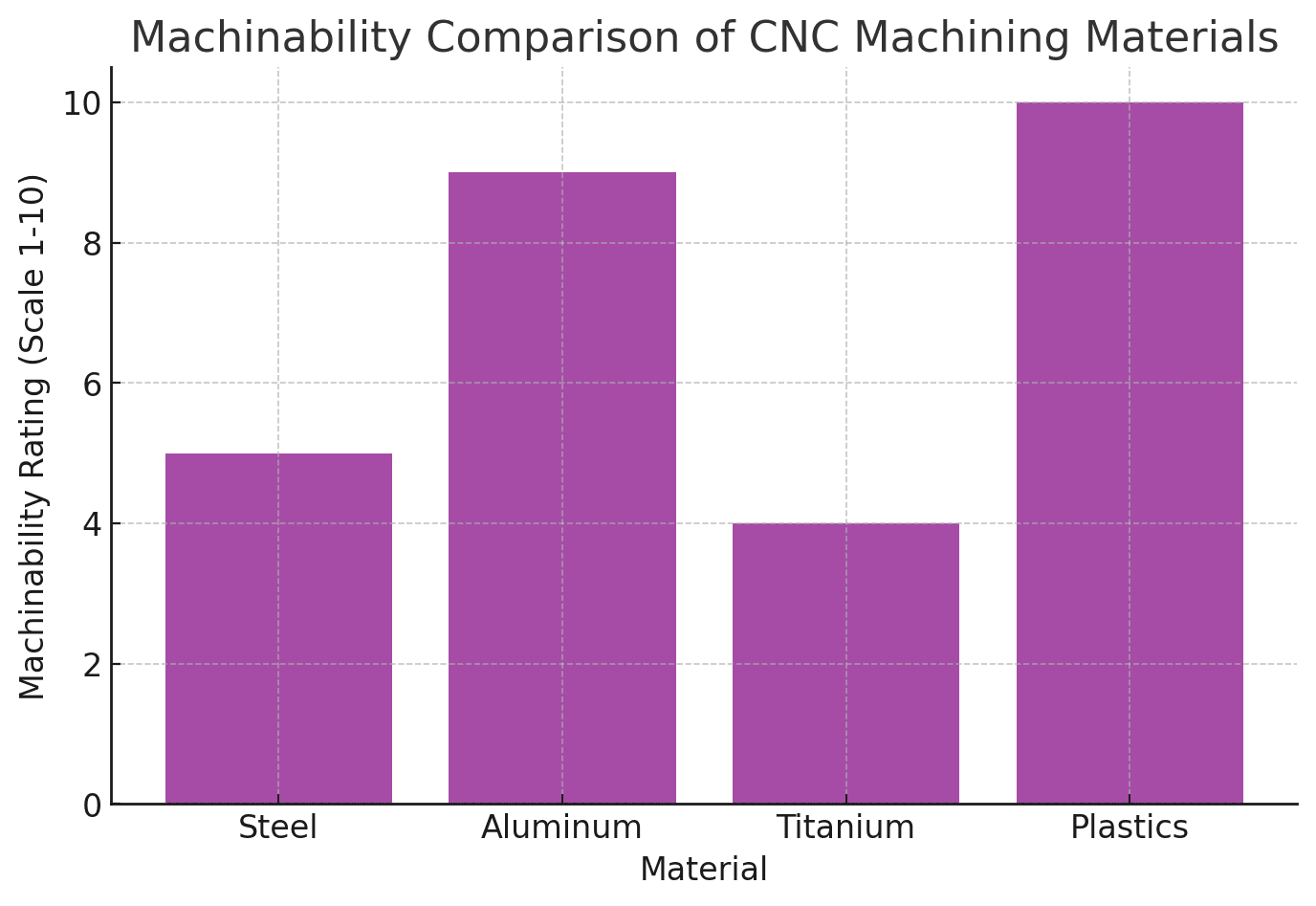

How to Select the Right Material for CNC Machining? When choosing a material for CNC machining, consider the following factors: Strength & Durability: Steel and titanium are best for high-load applications. Weight Considerations: Aluminum is preferred for lightweight parts. Corrosion Resistance: Stainless steel and titanium offer excellent resistance. Machinability & Cost: Plastics and aluminum are easier and faster to machine.

Conclusion Material selection is crucial in CNC machining as it determines the performance, durability, and cost-effectiveness of the final product. Steel, aluminum, titanium, and plastics each offer unique advantages for different applications. Manufacturers looking to optimize their CNC machining processes must carefully evaluate material properties and industry requirements.

Sahil Machines offers high-precision CNC machining solutions with expertise in working with a wide range of materials.

Visit us:www.sahilcnc.com

Inquiries: info@sahilcnc.com

Follow Sahil Machines for CNC industry updates!

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.