Smart Factories: How IoT is Enhancing CNC Efficiency

Introduction The manufacturing industry is undergoing a digital revolution with the rise of Smart Factories—facilities that integrate IoT (Internet of Things) technology to optimize efficiency, reduce downtime, and improve overall production quality. CNC machining, a critical component of modern manufacturing, is experiencing a major transformation as IoT-enabled systems drive automation and data-driven decision-making.

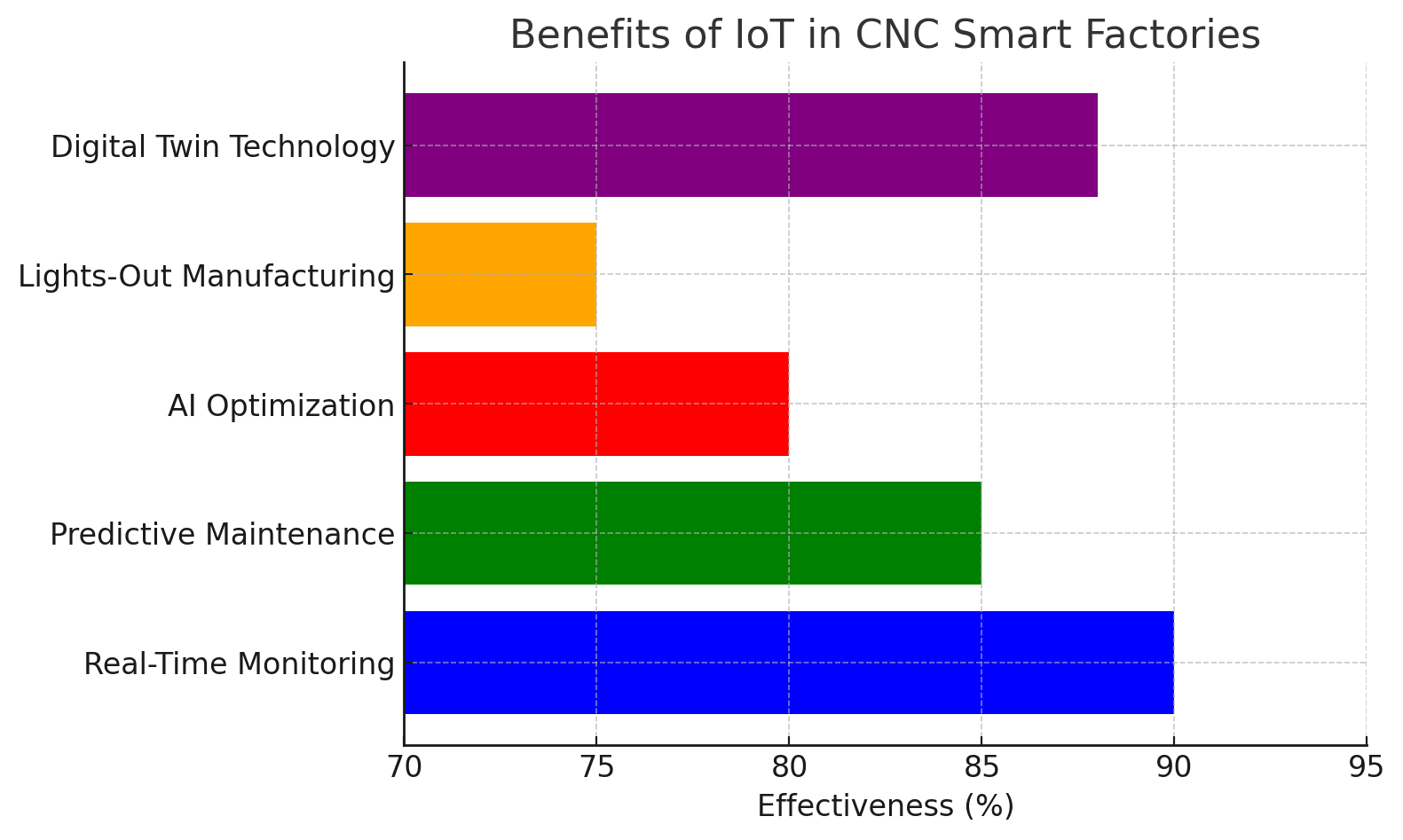

- Real-Time Machine Monitoring & Predictive Maintenance IoT sensors integrated into CNC machines provide real-time monitoring of critical performance parameters such as spindle speed, temperature, and vibration levels. This data enables predictive maintenance, helping manufacturers address potential failures before they occur.

Reduced downtime—Early detection of machine wear & tear

Increased lifespan—Proactive servicing of machine components

Minimized maintenance costs—Replacing parts only when necessary

2. Data-Driven Optimization for Higher Efficiency

IoT connectivity allows manufacturers to collect and analyze vast amounts of machining data. AI-powered machine learning algorithms help optimize CNC operations by adjusting feed rates, tool paths, and cutting speeds in real-time.

Automated adjustments for higher precision & reduced waste

Smart scheduling—Minimizing idle machine time

Remote monitoring—Access performance data from anywhere

- Enhanced CNC Automation & Lights-Out Manufacturing IoT-powered CNC machines are advancing lights-out manufacturing, where machines operate autonomously with minimal human intervention. Smart factories leverage robotic automation, AI-driven controls, and cloud-based systems to run CNC production lines 24/7. 24/7 unmanned operation—Boosting productivity Self-regulating CNC systems—Adjusting cutting parameters dynamically Seamless human-machine collaboration—Operators receive alerts only when intervention is needed

-

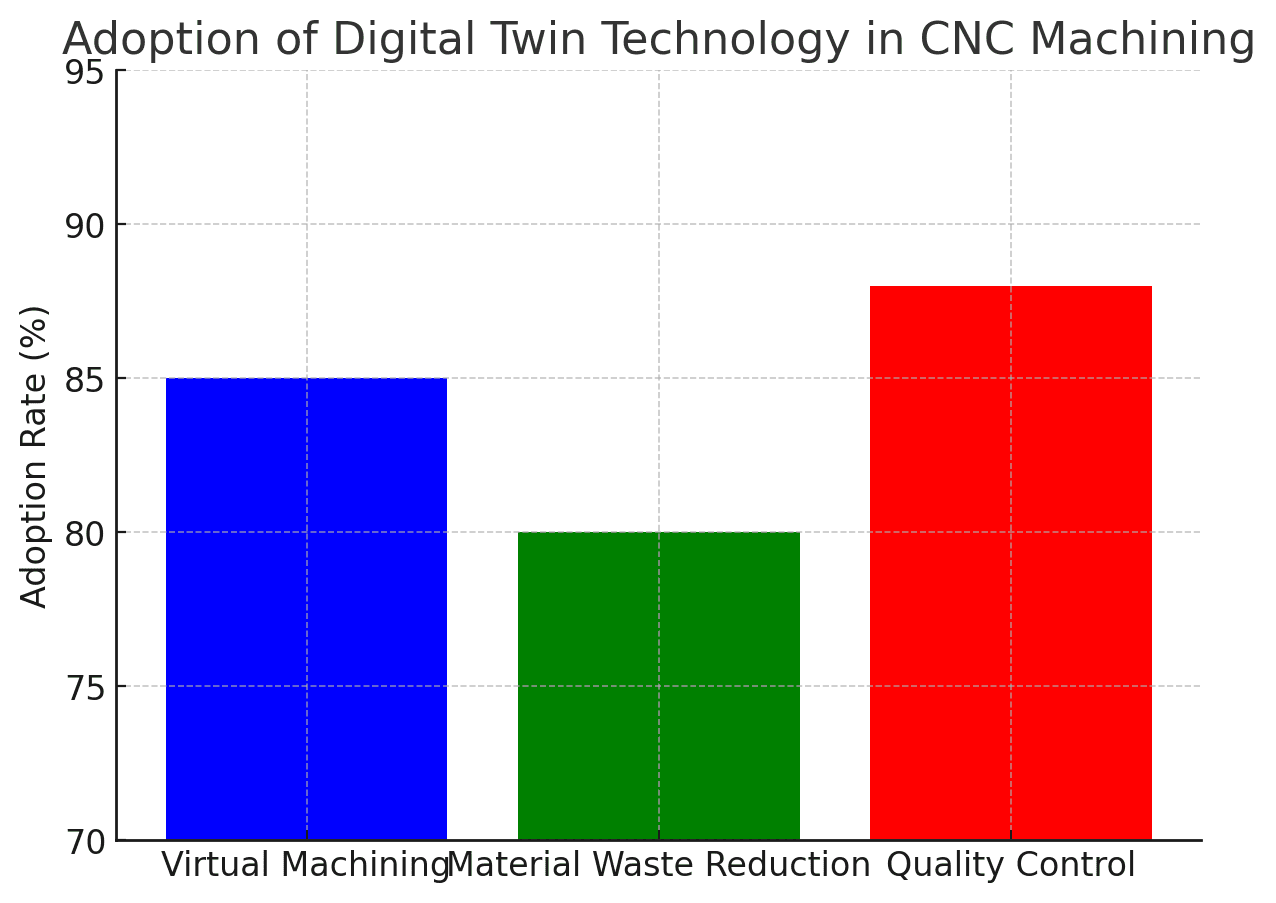

Digital Twin Technology A digital twin is a virtual replica of a CNC machine that simulates operations in real-time. IoT connectivity allows manufacturers to test machining strategies before execution, reducing errors and improving accuracy. Virtual machining—Test tool paths before real production Reduced material wastage—Identify inefficiencies beforehand

Enhanced quality control—Consistent and accurate production runs -

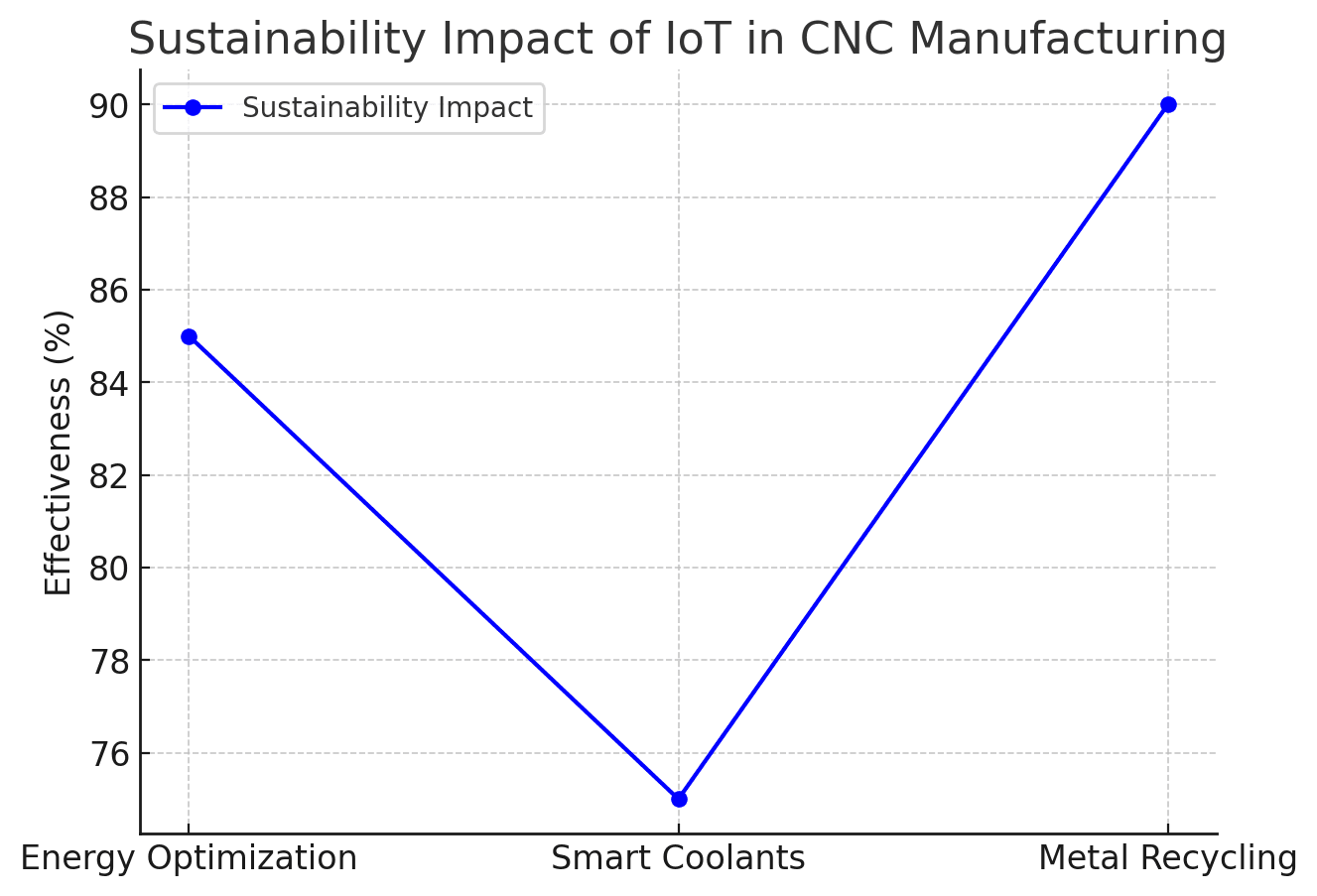

Sustainability & Energy Efficiency Smart factories are prioritizing eco-friendly CNC machining by leveraging IoT-based energy management solutions. CNC machines equipped with power-efficient motors and intelligent cooling systems are reducing the industry’s carbon footprint. Automated energy optimization—Lower power consumption by 20-30% Smart coolant systems—Minimizing waste in metal cutting Eco-friendly machining processes—Recycling metal chips and reducing emissions Conclusion The future of CNC machining is digital, driven by IoT advancements that enhance automation, efficiency, and sustainability. Smart factories leveraging real-time monitoring, predictive maintenance, AI-driven optimization, and digital twin technology are redefining the global manufacturing landscape.

Sahil Machines is at the forefront of this transformation, providing state-of-the-art CNC solutions powered by IoT and automation. Visit us: www.sahilcnc.com Inquiries: info@sahilcnc.com Follow Sahil Machines for more CNC industry insights!

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.