Understanding CNC Machine Specifications: A Buyer’s Guide

Introduction Selecting the right CNC machine for your business is crucial for achieving precision, efficiency, and cost-effectiveness in manufacturing. Whether you are in aerospace, automotive, or general machining, understanding CNC machine specifications ensures you make an informed purchase. This guide will help buyers navigate key CNC parameters and make the right choice.

-

CNC Machine Type & Configuration Different industries require different CNC machine types. The most common include: CNC Lathe – Ideal for cylindrical parts, shafts, and threads. CNC Milling Machine – Used for complex shapes, cutting, and drilling. CNC Vertical Machining Center (VMC) – Best for high-precision vertical milling operations. CNC Horizontal Machining Center (HMC) – Suitable for mass production and side-milling tasks. CNC 5-Axis Machine – Allows simultaneous movement on multiple axes for intricate parts.

-

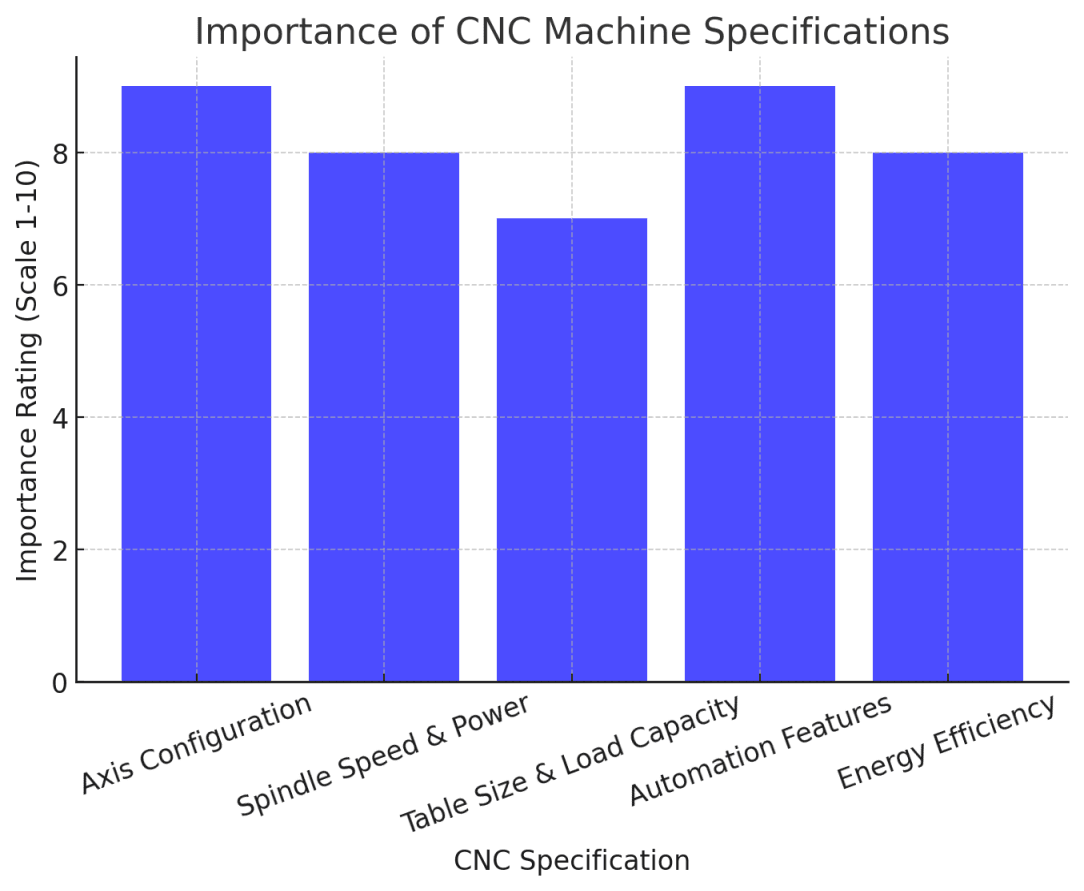

Key CNC Machine Specifications to Consider Before purchasing a CNC machine, buyers should evaluate the following specifications: Axis Configuration (3-Axis, 4-Axis, 5-Axis, or More) •Determines the machine’s ability to move tools and workpieces in different directions. •5-axis machines provide higher precision and minimize repositioning.

Spindle Speed & Power

•Higher spindle speeds (measured in RPM) improve surface finish and machining efficiency.

•Power (measured in HP or kW) determines the machine’s ability to cut tough materials.

Table Size & Load Capacity

•Determines the maximum workpiece size and weight the machine can handle.

•Essential for heavy-duty machining industries like railway and shipbuilding.

Rapid Traverse Rate & Feed Rate

•Rapid traverse rate measures how fast the machine moves when not cutting.

•Feed rate affects cutting speed and efficiency for different materials.

Tool Changer & Magazine Capacity

•Determines the number of tools the machine can hold for automated operations.

Larger capacity reduces manual intervention and increases production speed.

-

CNC Control System & Software The control system is the brain of a CNC machine, affecting ease of use and compatibility with CAD/CAM software. Leading CNC control brands include: Siemens – High precision and reliability. Fanuc – Popular for its widespread industry support. Heidenhain – Best for high-speed machining applications. Mitsubishi – Well-known for automation-driven CNC systems. Buyers should ensure the control system supports: G-Code Compatibility for standard CNC programming. Remote Monitoring & IoT Integration for real-time machine tracking. Automated Tool Path Optimization to reduce cycle time and enhance accuracy.

-

Material Compatibility & Cutting Capabilities Selecting a CNC machine based on material requirements is essential. Some machines specialize in cutting metals, while others excel in plastics or composites. Consider: Steel & Titanium Machining – Requires high torque and rigid machine structures. Aluminum & Brass Machining – Needs high-speed spindles for efficient cutting. Composite & Plastic Machining – Demands specialized tooling and vacuum beds.

-

Automation Features & Smart Technology With Industry 4.0, CNC machines are integrating automation and smart manufacturing features. Modern buyers should look for: Robotic Automation & Lights-Out Manufacturing for 24/7 operation. AI-Powered CNC Monitoring for predictive maintenance and error reduction. Digital Twin Technology for real-time simulation and optimization.

-

Energy Efficiency & Sustainability Sustainability is now a key factor in CNC machine selection. Buyers should look for: Energy-Efficient Motors that reduce power consumption. Eco-Friendly Coolants to minimize environmental impact. Metal Chip Recycling Systems to optimize material usage.

-

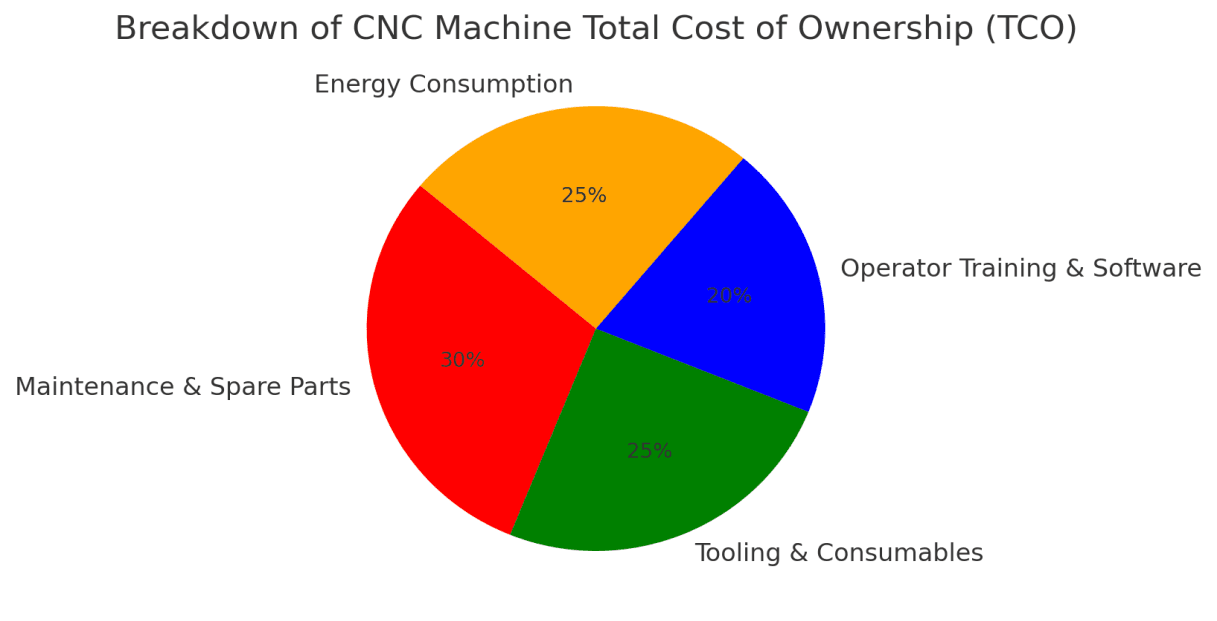

CNC Machine Pricing & Total Cost of Ownership Beyond the purchase price, consider the total cost of ownership (TCO), which includes: Maintenance & Spare Parts Costs Tooling & Consumables Expenses Operator Training & Software Licenses Energy Consumption & Operating Costs Investing in a high-quality, durable machine with a long lifecycle often provides a better return on investment (ROI) than lower-cost alternatives with frequent breakdowns.

Conclusion Understanding CNC machine specifications is essential for making a smart investment in machining technology. By carefully evaluating axis configuration, spindle power, software compatibility, automation capabilities, and sustainability features, buyers can choose the best CNC machine for their business needs. Sahil Machines offers a wide range of high-precision CNC solutions tailored for global industries. Our machines are designed for maximum efficiency, accuracy, and automation. Visit us: www.sahilcnc.com Inquiries: info@sahilcnc.com Follow Sahil Machines for more CNC industry insights!

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.