The Business Potential of CNC Job Shops & Contract Manufacturing

The CNC machining industry is experiencing a transformation, and CNC job shops & contract manufacturing are at the forefront of this evolution. With the growing demand for precision components across aerospace, automotive, medical, and industrial sectors, businesses are increasingly relying on contract CNC manufacturers for cost-effective and scalable production. As we move into 2025 and beyond, job shops leveraging automation, multi-axis machining, and digital transformation will see significant business growth.

- Rising Demand for CNC Job Shops Many industries require high-precision machining, but investing in in-house CNC infrastructure is costly. This is where contract CNC manufacturers and job shops offer an advantage: Scalable Production – CNC job shops can handle small-batch to large-scale production seamlessly. Cost Efficiency – Outsourcing to CNC shops eliminates expensive machine investments. Industry Versatility – Serving aerospace, automotive, medical, and energy industries.

-

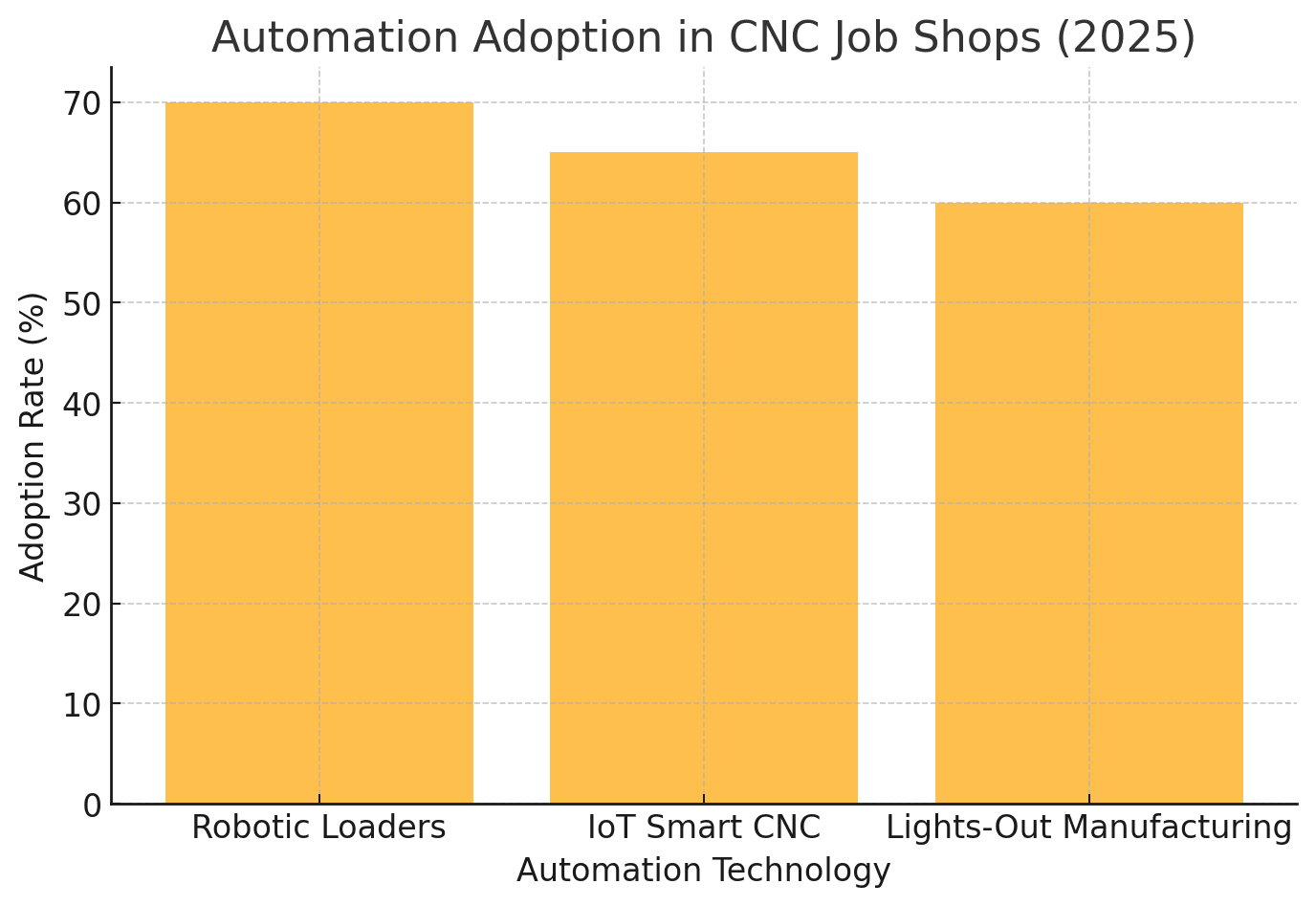

How Automation is Boosting CNC Contract Manufacturing The adoption of automation & lights-out machining is allowing CNC job shops to operate with higher efficiency and lower costs. Robotic Loaders & Unloaders – Reduce manual handling, improving accuracy & speed. IoT-Enabled Smart CNC Machines – Offer real-time monitoring & predictive maintenance. 24/7 Lights-Out Manufacturing – Continuous production with minimal human intervention. This shift is increasing the profitability of CNC job shops, as they can deliver faster turnaround times while maintaining precision.

-

Key Industries Driving CNC Job Shop Growth Several industries are outsourcing CNC machining more than ever: Aerospace & Defense – Complex components requiring high-precision CNC machining. Automotive & EV Manufacturing – CNC parts for electric vehicles (EVs) and battery systems. Medical & Healthcare – CNC-machined implants and surgical tools demand extreme accuracy. Oil & Gas – Custom-machined parts for drilling and refining operations. Companies that specialize in contract CNC manufacturing for these high-growth sectors will experience higher profitability & demand.

-

Sustainability & CNC Job Shops With industries moving toward sustainable manufacturing, CNC job shops are implementing eco-friendly machining techniques: Energy-Efficient Motors – Reducing power consumption by 20-30%. Water-Based Coolants – Minimizing chemical waste. Recycling Metal Chips – Lowering material costs while reducing waste. Governments are offering incentives for CNC shops that integrate green manufacturing, making sustainability a competitive advantage.

-

Emerging Markets & CNC Job Shop Growth Countries like India, Vietnam, and Brazil are becoming global CNC manufacturing hubs. Factors driving this growth include: Lower labor & operational costs compared to Western markets. Government support & tax incentives for CNC automation. Rising demand for precision parts across industrial sectors. By expanding into these emerging markets, CNC job shops can scale operations and maximize profits.

Conclusion: The Future of CNC Job Shops & Contract Manufacturing The CNC job shop model is evolving with automation, AI-driven machining, and global expansion. Businesses that embrace digital transformation, adopt smart CNC systems, and explore emerging markets will thrive in 2025 & beyond. Sahil Machines is at the forefront of CNC contract manufacturing, delivering high-precision solutions for industries worldwide. Visit us:www.sahilcnc.com Inquiries: info@sahilcnc.com Follow Sahil Machines for more CNC industry insights!

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.