The Impact of Global Supply Chain Issues on the CNC Industry

Introduction In recent years, the global supply chain has faced unprecedented disruptions due to geopolitical tensions, raw material shortages, transportation delays, and economic uncertainty. These challenges have significantly impacted the CNC machining industry, affecting production schedules, component availability, and overall cost structures. As we move further into 2025, CNC manufacturers must adapt to these changing dynamics to maintain efficiency and competitiveness.

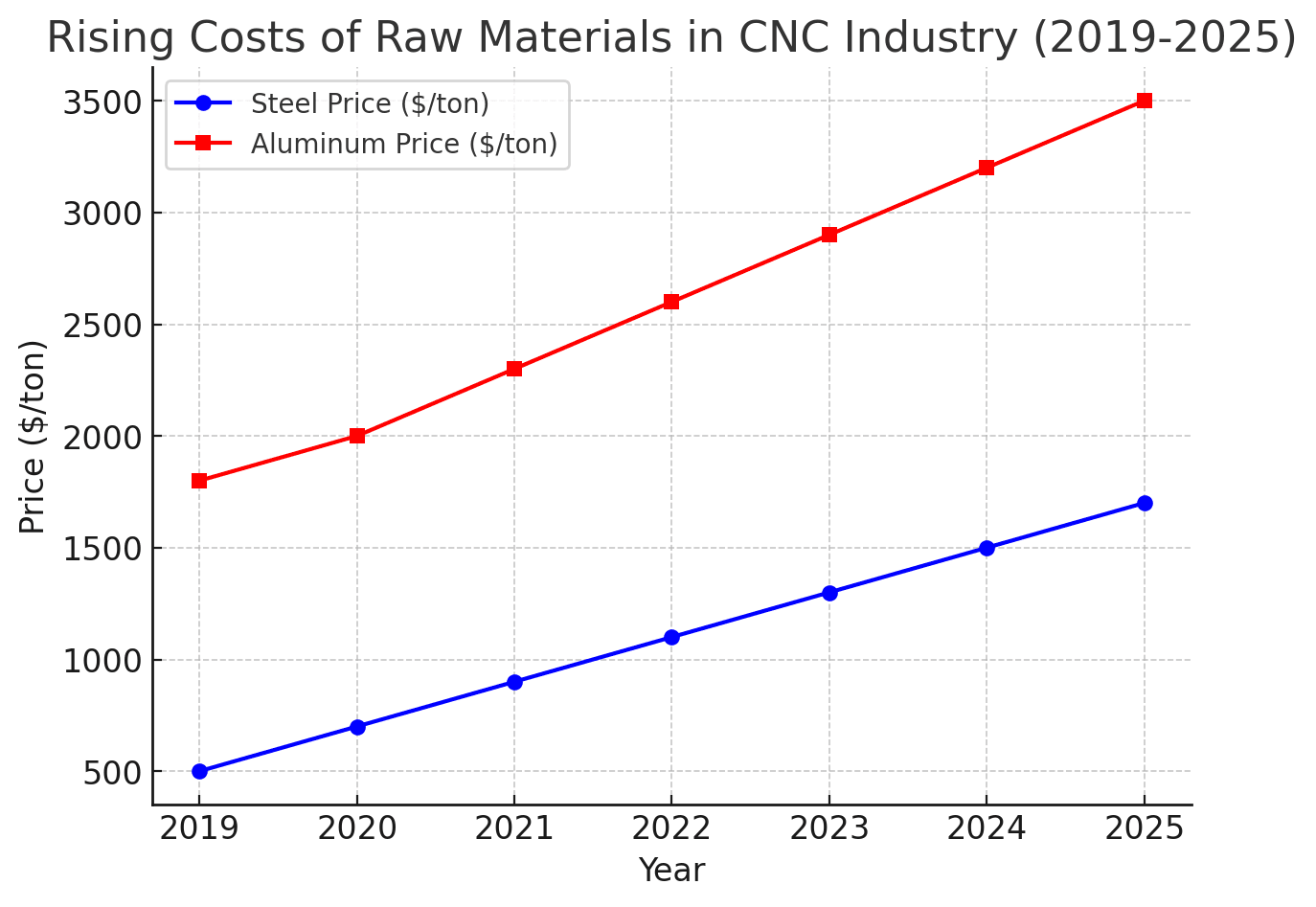

- Raw Material Shortages & Rising Costs CNC machining relies heavily on metals like aluminum, steel, and titanium. However, disruptions in global metal supply chains have caused: Higher raw material costs, impacting profit margins Longer lead times, delaying production and deliveries Increased demand for alternative materials, such as composites and hybrid alloys Industry Insight: Manufacturers are now diversifying their supplier base and localizing procurement strategies to reduce dependency on a single region.

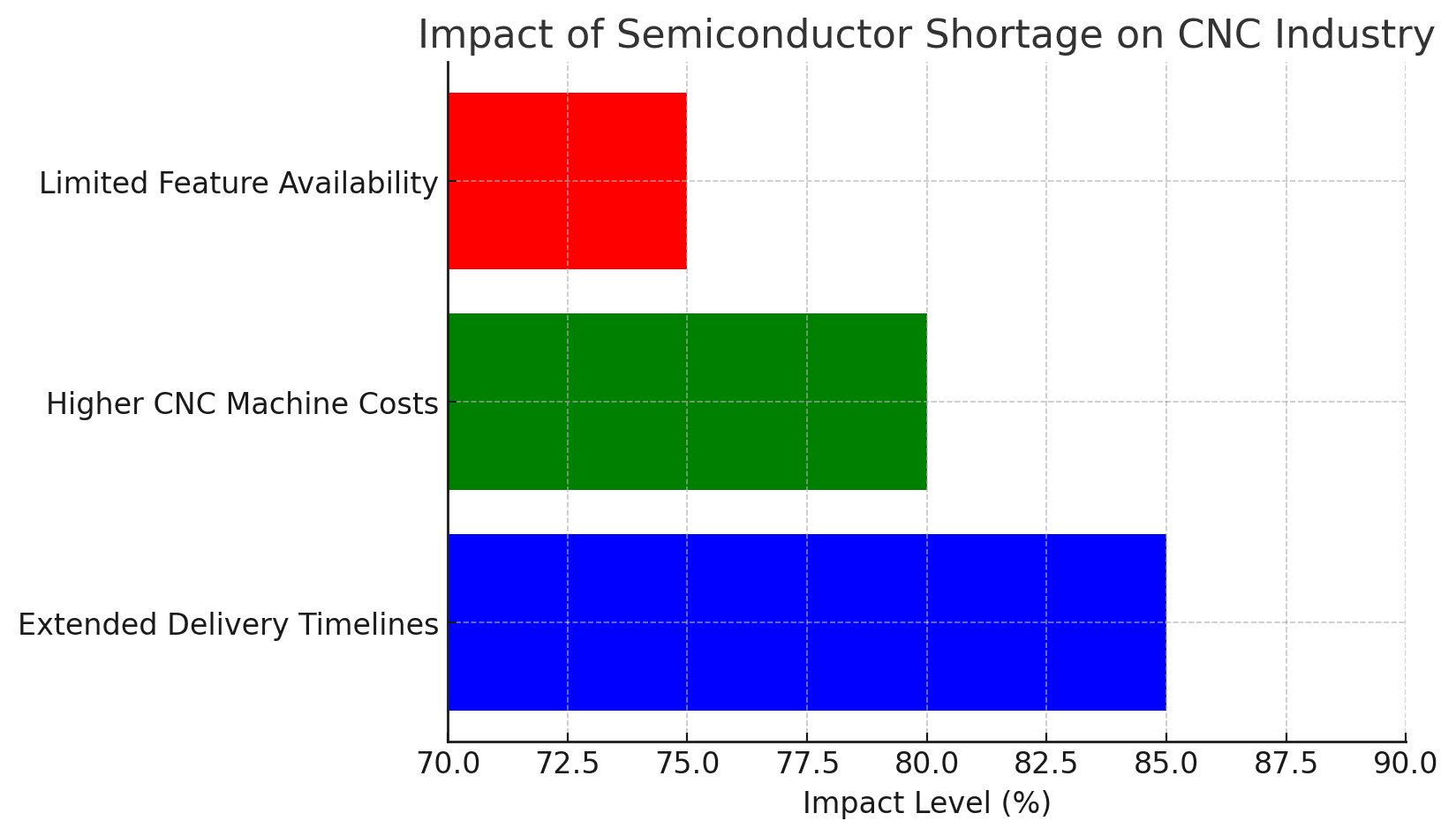

- Semiconductor Shortage Impacting CNC Controllers The global semiconductor shortage has created challenges in the production of CNC controllers and automation systems. This has led to: Extended machine delivery timelines, slowing down expansion projects Higher CNC machine costs, increasing capital investment requirements Limited availability of advanced features, delaying technological adoption Solution: Leading CNC brands are investing in R&D to develop more energy-efficient and software-driven controllers that minimize reliance on scarce semiconductor components.

-

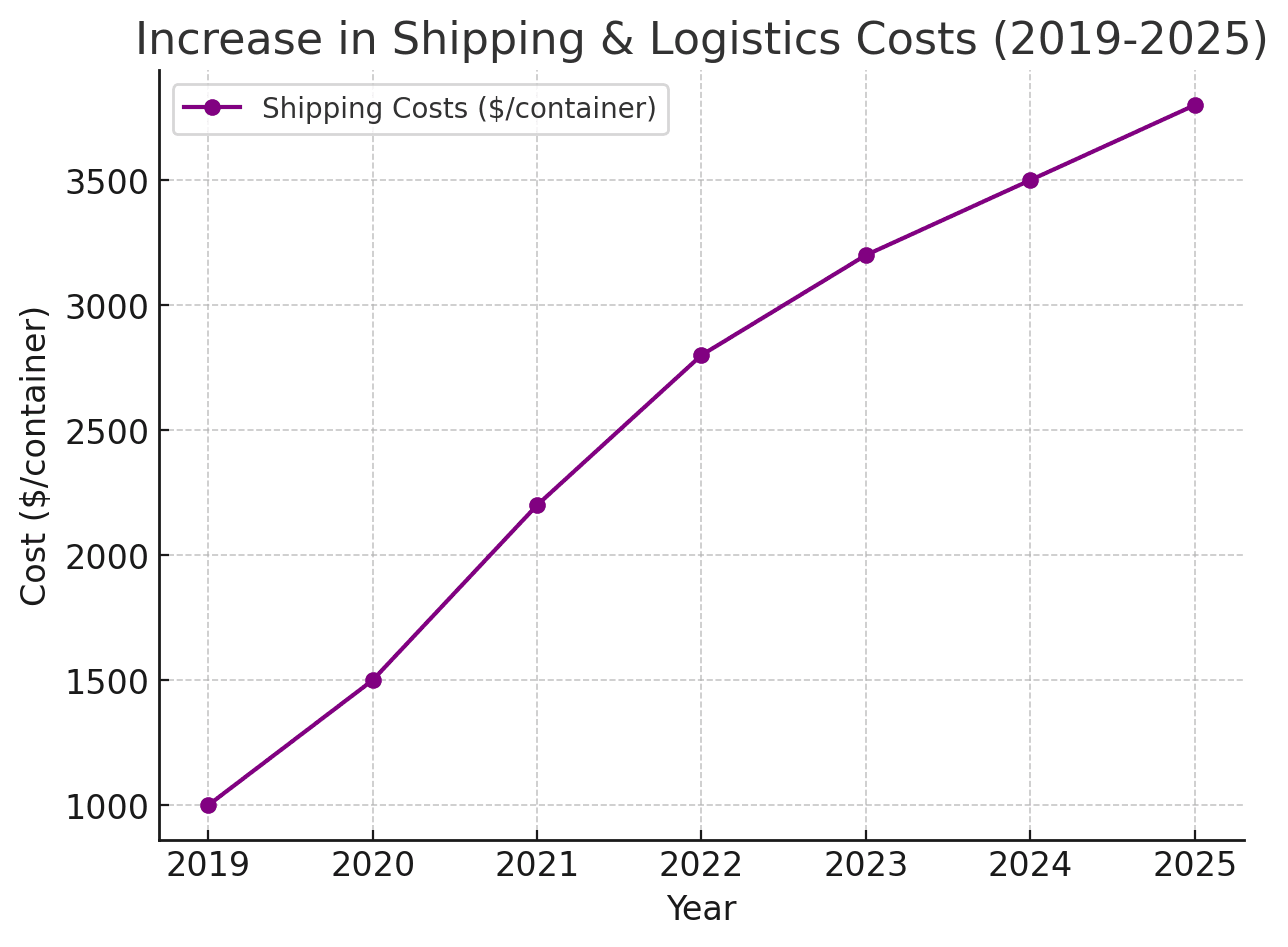

Shipping & Logistics Delays Freight costs and shipping disruptions have escalated due to port congestion, labor shortages, and fluctuating fuel prices. This affects CNC manufacturers in several ways: Delayed import of machine components, leading to production slowdowns Rising transportation costs, increasing the final price of CNC machines Uncertainty in global trade policies, requiring supply chain flexibility Adaptive Strategies: Companies are shifting towards regionalized production hubs to mitigate risks and reduce lead times.

-

Shift Toward Reshoring & Localized Manufacturing To counter supply chain disruptions, many CNC manufacturers are moving towards reshoring—bringing production closer to home. Key benefits include: Reduced dependency on foreign suppliers, enhancing supply chain resilience Faster turnaround times, improving customer satisfaction Government incentives & tax benefits, supporting local industries Future Outlook: The CNC industry will see an increased focus on automation and AI-driven manufacturing to enhance efficiency and reduce reliance on manual labor.

-

CNC Industry’s Role in Strengthening Supply Chains The CNC industry itself plays a crucial role in strengthening global supply chains by producing precision components used across aerospace, automotive, and defense sectors. Advancements in CNC technology are helping industries overcome challenges through: AI-powered predictive maintenance, reducing downtime Hybrid CNC & 3D printing, minimizing material waste Energy-efficient CNC machines, lowering production costs

Conclusion Global supply chain disruptions continue to reshape the CNC machining industry, pushing manufacturers toward diversification, reshoring, and technological advancements. Companies that invest in smart manufacturing, automation, and alternative sourcing strategies will gain a competitive edge in the evolving industrial landscape.

Sahil Machines is at the forefront of these innovations, ensuring uninterrupted supply and precision CNC solutions for global industries. Visit us:www.sahilcnc.com Inquiries:info@sahilcnc.com Follow Sahil Machines for industry insights & updates!

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.