The Role of CNC Machining in Aerospace & Aviation Industry

Introduction The aerospace and aviation industry demands unmatched precision, durability, and efficiency in component manufacturing. CNC (Computer Numerical Control) machining has become the backbone of modern aerospace production, ensuring the highest standards of accuracy and performance. From turbine blades to fuselage components, CNC machining is shaping the future of aviation.

-

Precision & High-Performance Materials Aerospace parts require extreme precision, often with tolerances as tight as 0.0001 inches. CNC machining enables manufacturers to work with high-performance materials like: Titanium – Lightweight & corrosion-resistant, ideal for aircraft frames and engine parts. Inconel – Heat-resistant alloy used in jet engines. Carbon Fiber Composites – Strong, lightweight materials enhancing fuel efficiency.

-

CNC Machining for Aircraft Structural Components CNC technology is widely used to manufacture critical structural parts such as: Turbine Blades & Jet Engine Components – CNC machining ensures perfect aerodynamic shapes for optimal engine efficiency. Landing Gear Parts – High-strength CNC-milled steel and titanium components ensure safety under extreme stress. Fuselage & Wing Components – Precision-cut aluminum and composite materials reduce weight while maintaining structural integrity.

-

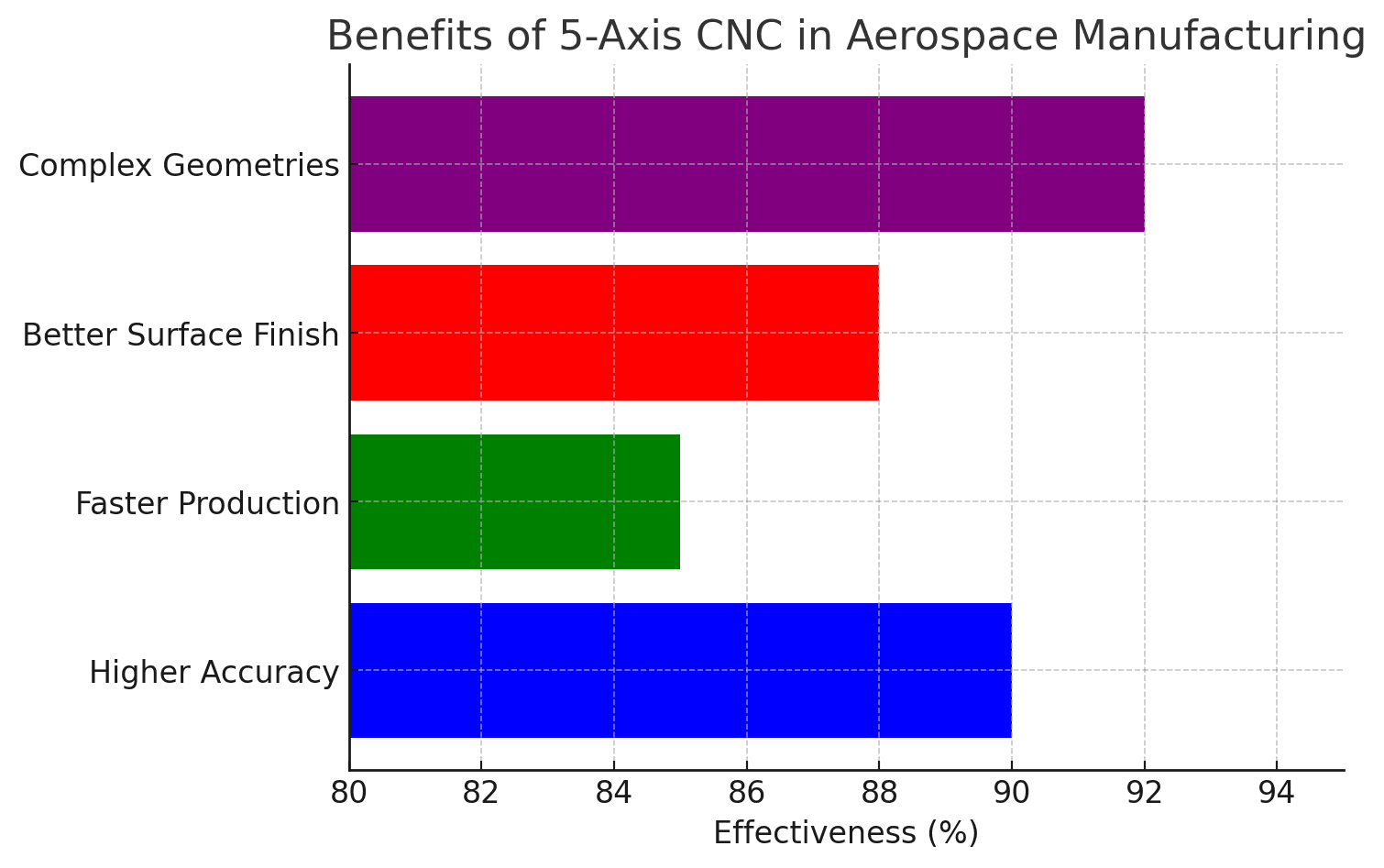

Multi-Axis CNC for Complex Aerospace Parts Traditional machining methods struggle with the complexity of aerospace parts. 5-axis CNC machining revolutionizes aircraft component production by:

Reducing manual repositioning, increasing accuracy. Creating complex geometries in a single setup, improving efficiency. Enhancing surface finishes for aerodynamically optimized parts. -

CNC Automation & Lights-Out Manufacturing in Aerospace Aerospace manufacturers are increasingly adopting fully automated CNC production lines, allowing for: 24/7 lights-out manufacturing with minimal human intervention. Real-time monitoring & predictive maintenance, reducing downtime. AI-powered toolpath optimization, improving machining speed & reducing material waste.

-

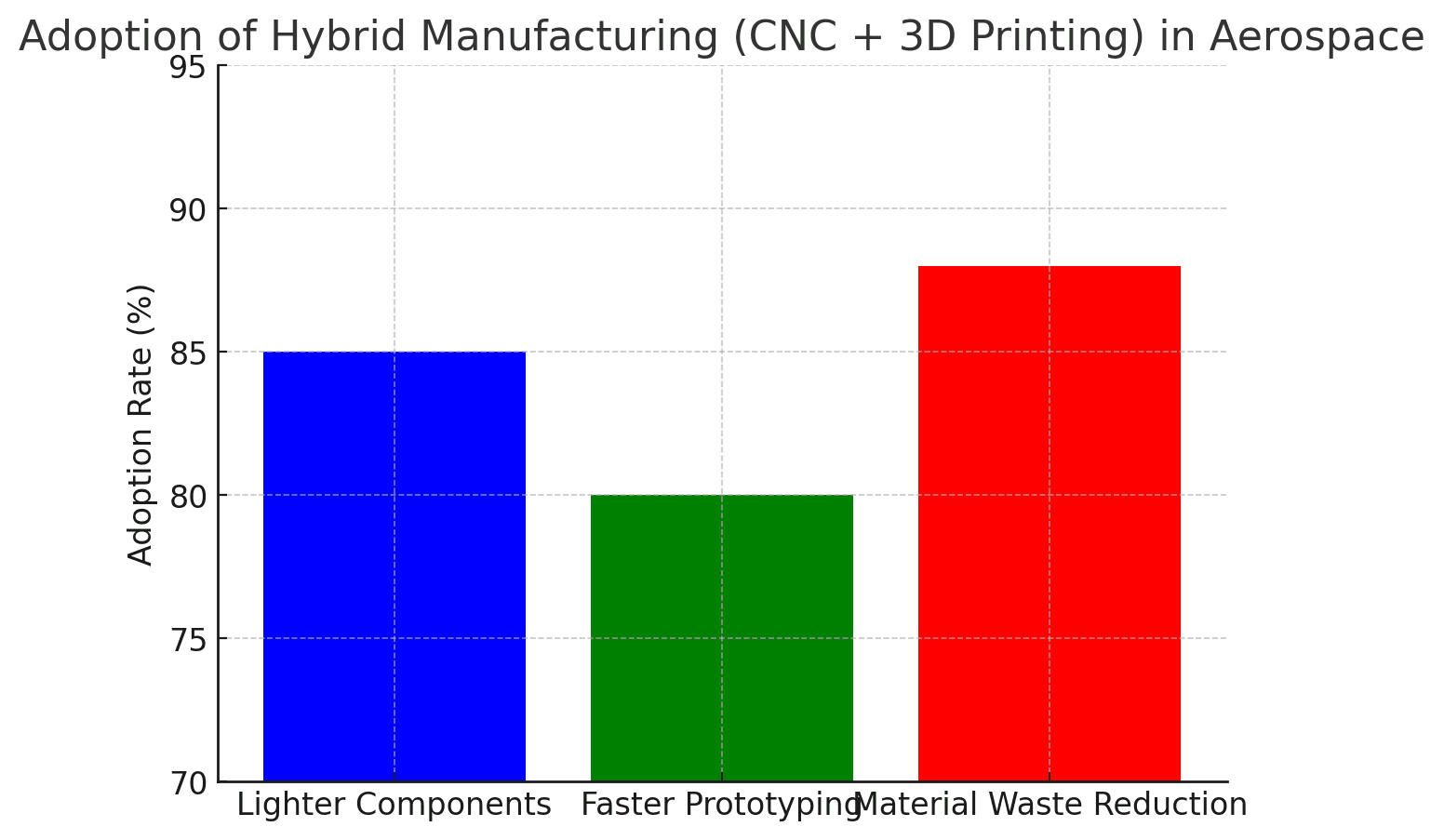

Hybrid Manufacturing: CNC Machining + 3D Printing The combination of CNC machining and additive manufacturing (3D printing) is transforming aerospace manufacturing by: Producing lighter, high-strength components for aircraft. Enabling faster prototyping, cutting development time by 50%. Reducing material waste while maintaining aerospace-grade precision.

-

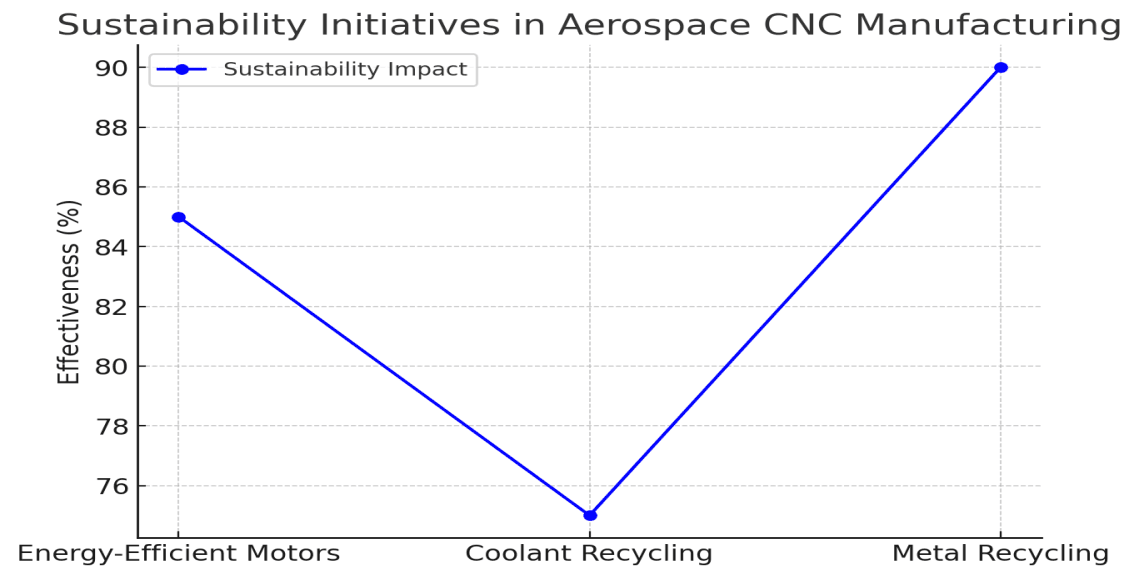

Sustainable & Cost-Efficient CNC Aerospace Manufacturing Sustainability is a growing focus in the aerospace sector. CNC machining contributes to eco-friendly aviation through: Energy-efficient motors, reducing power consumption by 30%. Water-based coolants, minimizing hazardous waste. Metal recycling processes, cutting material costs.

- The Future of CNC in Aerospace As aviation technology advances, CNC machining will continue to evolve with AI-driven software, cloud-based CNC control, and digital twin technology. These innovations will: Improve real-time quality monitoring. Enable remote manufacturing operations. Reduce lead times with automated toolpath adjustments. Conclusion

The aerospace industry relies on CNC machining for its unmatched precision, efficiency, and ability to work with advanced materials. As automation, hybrid manufacturing, and AI-driven CNC software become mainstream, aerospace manufacturers will achieve greater efficiency, sustainability, and innovation. Sahil Machines is at the forefront of CNC innovation, providing high-precision solutions for the aerospace industry. Visit us: www.sahilcnc.com Inquiries: info@sahilcnc.com Follow Sahil Machines for the latest CNC industry insights!

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.